China granulated blast furnace slag fine powder wholesale price

- $30.00 / >=10000 metric tons

- 10000 metric tons

- Tangshan City Secai Trading Co., Ltd.

- Hebei, China

- Ms Linda Zhao

Product Detail

| model: | GGBFS | Flow ratio: | Minimum 95% |

| Package preview: | density: | Minimum 2.80g/cm3 | |

| port: | Port of Tianjin, China | design style: | All styles |

| payment terms: | Letter of credit, wire transfer | Project solution capabilities: | others |

| Place of origin: | China | Moisture content: | Maximum 1% |

| brand: | SC | Fineness: | Minimum 400m2/kg |

| After-sales service: | Online technical support | Activity Index: | Minimum 7 days: 75% Minimum 28 days: 95% |

| Supply capacity: | 1,500,000 tons per year | Loss on ignition: | Maximum 3% |

| application: | cement | Sulfate (as SO3): | Maximum 4% |

| Packaging details: | Bulk | Chloride (CI): | Maximum 0.06% |

| Warranty: | 1 year |

Granulated blast furnace slag powder (GGBFS) is a recyclable material produced when slag from molten iron ore is rapidly quenched and then ground into a powder.

In general, GGBFS concrete develops strength more slowly than ordinary Portland cement (OPC) concrete, but exhibits higher strength after one year. GGBFS concretes are also less permeable, but they develop unusual pore systems. The performance of GGBFS concrete depends not only on the amount of GGBFS used, but also on the chemical composition of the other materials in the mix. This part of the project will investigate three different GGBFS replacement levels: 0%, 30% and 50%. Thirty percent is the most commonly used replacement level. This means that 30% of the cement materials in concrete are GGBFS and 70% are OPC. The project will study the performance compared to 100% OPC concrete (0% GGBFS) and will determine whether the 50% level is a reasonable alternative level. Along with the GGBFS surrogate level variable, four different cement brands and two coarse aggregate types will be used to determine their different material properties. The mixture will also be created and cured at 40 degrees Fahrenheit to determine the performance of GGBFS concrete at lower temperatures.

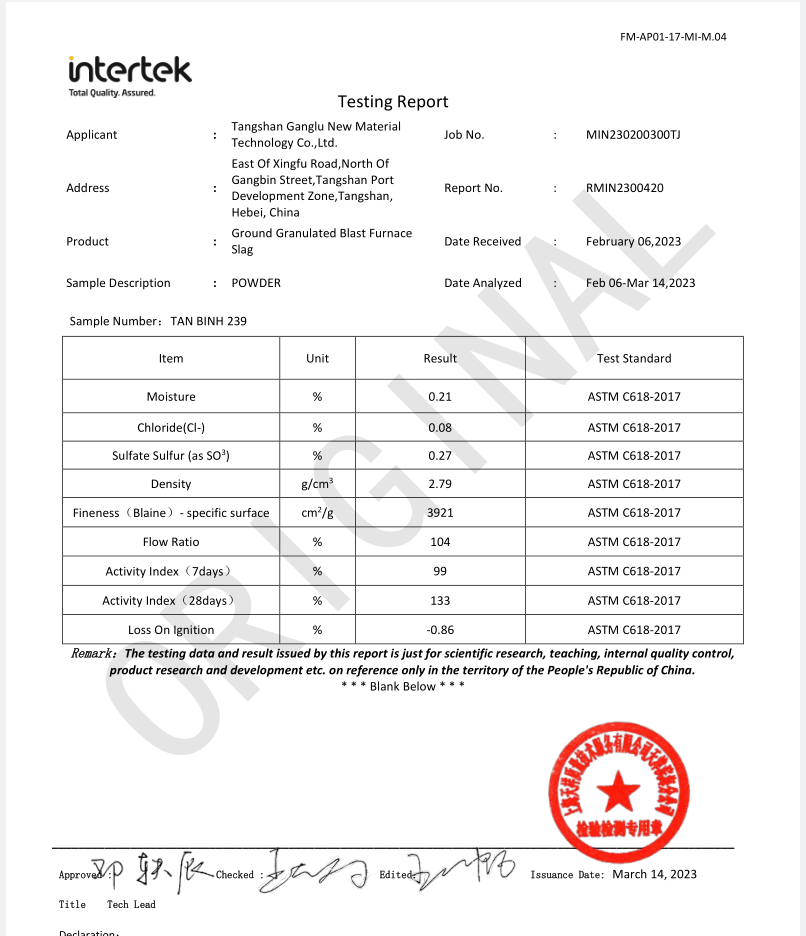

| project | GB/T 18046-2008(BS EN 15167-1:2006) |

| Fineness | Minimum 400m2/kg |

| density | Minimum 2.80g/cm |

| activity index | Minimum 7 days: 75% Minimum 28 days: 95% |

| Flow ratio | Minimum 95% |

| Sulfate (as SO3) | Maximum 4% |

| Chloride(CI) | Maximum 0.06% |

| Loss on ignition | Maximum 3% |

| Moisture content | Maximum 1% |

Our company adheres to the concept of environmental protection and insists on smoke-free products from appearance to the entire packaging process, and contributes its own strength to environmental protection.

Related Products

-

No defoaming agent, high white 95% gypsum powder, clone fragrance, no shrinkage painting gypsum, high flow gypsum powder technology

Product Description phosphorusRomesenitrogenoxygenSecondubles Hoopswatthaight98% HoopsHenthusiasm8.5MPa We are your best supplier. 1.We areTopgramsupplierIn China 2. We have our ownprofessionalR&D team 3.promiseNo air bubbles, no defoamer Application scenarios Product advantages and features: No...... -

High quality gypsum plaster powder Egypt origin packaging 20&25&40 kg pp bag gypsum powder plaster

Package: 25kg/40kg/50kg/1000kg/bag usage: Building materials mold model port: Sohna - Damietta - Alexandria - Port Said East - Port Said West raw material: Natural gypsum raw stone Warranty: 1 year Origin: Egypt Project solving capabilities: others design style: traditional After-sales service:...... -

The joint composition of the ready mixture for the interior wall

application: hotel Packaging Details: export package Project Solution Capabilities: others Supply capacity: 3000 barrels per month port: Qingdao Material: Gypsum powder After-sales service: online technical support design style: modern Origin: China Package: 25.50kg/barrel color: White Warranty:...... -

Promise Bubble Free Whiteness 95% Pop Aroma Clone Black Spot Free Plaster of Paris for Diy Lamp Silicone Mold

bubble: Completely free of air bubbles on the surface and inside Warranty: 2 years Fineness: 2400 mesh fluidity: 18 cm or more Package preview: Gouache ratio: 26/100 application: Silicone Mold, DIY, Craft, Casting payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Origin: Guangdong, China..... -

Egyptian high quality gypsum powder gypsum Of Paris 0020 1027113228 International For Building Materials Gypsum

application: Hotel, Villa, Hospital Packaging Details: :20&25&40 KG(-/+2%)PP bag Warranty: 1 year brand: plaster soda Package preview: payment terms: contact us design style: industrial port: SOKHNA-DAMIETTA-ALEXANDRIA-PORT SAID EAST-PORT SAID WEST Supply capacity: 1000 tons per day Origin: Egypt...... -

High Hardness 8.5 Mpa Pop Clone Dimensional Stability Quick Drying Super Hard Plaster of Paris for Home Diy Wallart Background

Initial setting time/final time: 6/20 minutes, custom Flexural strength MPa: 8.0MPa, 8.5MPa Project solution ability: Graphic design, 3D model design Fineness: 2400 mesh fluidity: over 18 cm Surface smoothness: glass surface Origin: Guangdong, China color: all colors are available model: TC05...... -

Promise-free bubble-free high hardness 8.5Mpa gypsum powder aroma non-deformable painting gypsum gypsum powder adult mold

Surface smoothness: glass surface Package preview: color: all colors are available payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram bubble: Completely free of air bubbles on the surface and inside Flexural strength MPa: 8.0MPa, 8.5MPa Initial setting time/final time: 6/20 minutes, custom.... -

Professional Custom White Gypsum Powder Waterproof Decoration Supplier Gypsum

application: Building Construction port: Shenzhen Port feature: Adhesion Package: 40kg/bag brand: Luzhou Mortar Origin: Yun Nan China Supply capacity: 5000 tons per month Advantage one: insulation After-sales service: online technical support, other Advantage: sound insulation shape: powdery type:..... -

Construction material gypsum powder price per ton

Supply capacity: 1000 tons per month usage: interior or exterior port: Qingdao Package: 20kg/25kg/40kg/50kg per bag sample: free After-sales service: online technical support Project solution ability: overall project solution product name: Building material gypsum powder price per ton color: White..... -

POP molding gypsum powder high strength ultra high strength chemical source Egyptian gypsum

model: CS G01 After-sales service: online technical support Supply capacity: 4000 tons per month design style: traditional, traditional Package preview: port: Port of Sokhna and Alexandria CaSO4 2H2O: 95% Project solution ability: available, the overall solution of the project, no what app:......