low glass

- $10.00 / >=100 square meters

- 100 square meters

- Guangzhou Shunzhifa Glass Co., Ltd.

- Guangdong, China

- Mr BOB YU

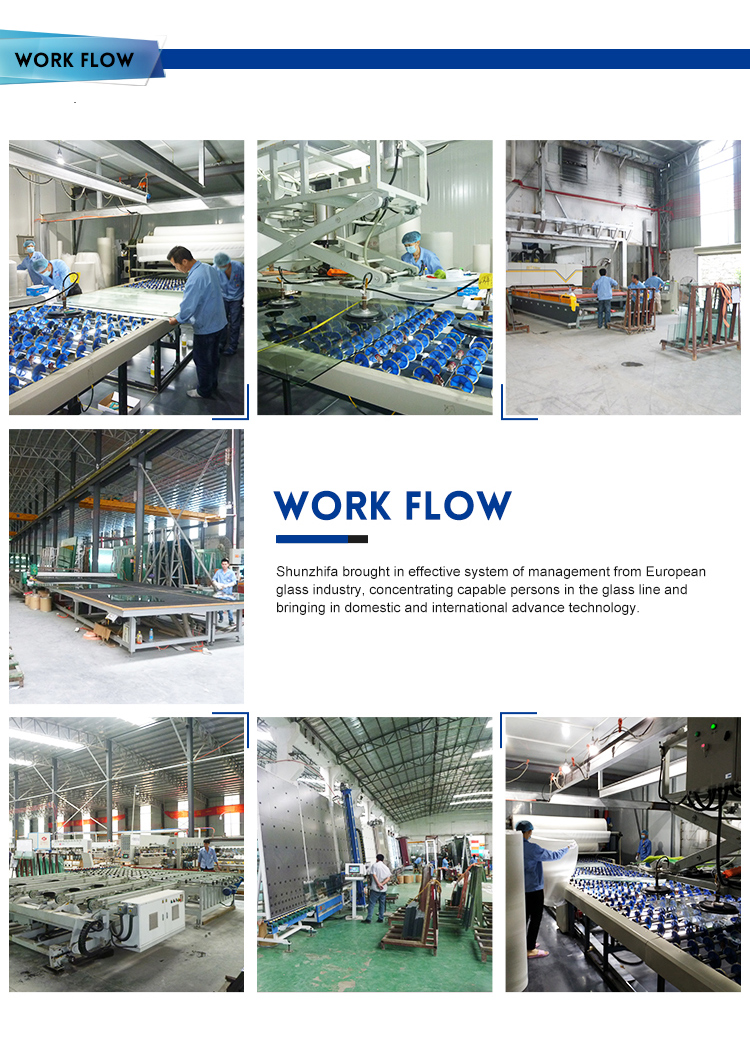

Product Detail

| Packaging Details: | Low-e glass All flat glass is guaranteed A1 quality and packed in strong seaworthy wooden boxes in paper or expanded polyethylene pearl wool (EPE). Stainless steel and plastic will be used to strengthen the packaging. | model: | Shunzhifa |

| Package preview: | usage: | industrial | |

| Supply capacity: | 15000 square meters per month | brand: | Shunzhifa |

| Warranty: | over 5 years | Origin: | Guangdong, China |

| structure: | hard | After-sales service: | Returns and Exchanges |

| thickness: | 12mm, 1mm-19mm | shape: | flat |

| payment terms: | L/C, Western Union, T/T | Project Solution Capabilities: | overall project solution |

| application: | patio | port: | Guangzhou |

low-e glass

(Heat reflective glass) adopts horizontal magnetron high-speed sputtering coating. It can effectively control the transmission of visible light and low infrared rays.

Coated glass has a high reflectivity to sunlight, and the reflectivity can reach 20%~40%, so it can save the energy consumption of indoor air conditioners, and has good shading effect, making the indoor light softer and more pleasant.

It is available in a wide range of shades and can bring a striking look to any building. In addition to being beautiful, it can also balance the transmittance of light and make the room more comfortable. Visible light reflection and solar interception can reduce your cooling costs.

Scope of application: 1) Building doors and windows 2) Towers and building curtain walls 3) Cultural facilities and article decoration

Leybold Coated Glass offers high-performance reflective glass with a robust coating that is resistant to acid and abrasion. The coating guarantees high performance for ten years.

GVG's technicians are dedicated to producing fashionable colors with their proficiency and experience. Buildings with GVG glass look modern and sophisticated.

Coated Glass Installation Instructions

1. Cutting process

2. Divided into optical coating surface and glass surface. When cutting coated glass into small pieces, the glass surface should be placed flat on the workbench, and the cutting workbench should be kept clean and free of foreign objects; the gap at the edge of the glass should be straight and smooth.

3. Storage and transportation: When the coated glass is transported to the buyer, each piece of glass should be separated by foam plastic paper, and the surface of the coated glass can be directly touched; the coated glass should be placed in a room with dry air, good ventilation, and no corrosive gas, but It is strictly forbidden to store in the open air.

4. Installation and construction

(1) After the cement, mortar and paint works are completed, install the coated glass; but if the coated glass is installed facing the outdoors, the coated surface should face the indoor wall.

(2) The edges around the glass are sealed with elastic materials, and the glass glue should be neutral.

(3) The seam distance on each side should be kept above 7mm, and the groove depth of the glass should be kept between 1.5 and 2.2mm. There must be a frame structure around the window frame, and a soft filler block must be placed on the bottom of the glass. The periphery of the glass shall not be in direct contact with the frame and hard materials.

Related Products

-

LED lens directly press H-K9L Plano convex light glass lamp LED LED lens aspherical for automatic cars

Product Description Specification Packaging and delivery In order to better ensure your products are safe, professional, environmentally friendly, convenient and efficient packaging services. Company information Semi-automatic pet bottle blower bottle manufacturing machine bottle mount machinePet...... -

Customized Plano-Convex Optical Lighting Borosilicate Glass LED Optical Lens for Automotive

shape: curve usage: Industrial lighting brand: Gabriel payment terms: Letter of Credit, Telegraphic Transfer structure: hard Warranty: 1 year model: 30 mm After-sales service: Returns and Exchanges, No, Field Installation, Yes Project solving capabilities: Overall project solution, 3D model design..... -

Top quality gold plated broken glass aggregate for terrazzo table tops 1-3mm coated glass sand for arts and crafts design

thickness: 1-3mm Package preview: shape: irregular use: terrazzo, landscaping, swimming pool, aquarium, DIY Minimum order quantity: 1 ton Payment: L/C, T/T, Western Union payment for offline orders color: gold plated Material: coated clear glass Project solution capabilities: others payment terms:..... -

High quality 4mm 4.5mm 4.6mm 5mm 1830*2440mm kitchen color back-painted glass

shape: flat After-sales service: Returns and exchanges, none, online technical support, on-site training, on-site installation, free spare parts technology: Transparent glass, stained glass, coated glass, patterned glass, delivery time: 10-15 days Supply capacity: 400 cubic meters per day...... -

Hard Online Low Glass 3mm 4mm 5mm 6mm 8mm 10mm 12mm

maximum. size: 6500*3300mm Project Solution Capabilities: others Glass type: Hard in-line Low E glass use: Windows, doors and curtain walls Warranty: 5 years color: to clear Packaging Details: plywood crate application: Supermarkets, workshops, schools, home offices, outdoors, living rooms, office..... -

Sound-insulating vacuum glass tempered transparent heat-insulating vacuum glass for exterior glass of high-rise buildings

brand: super technology thickness: 6.5mm-38.5mm,6.5mm-38.5mm Operating temperature: -60~100℃ shape: flat color: to clear model: STVIG-11 Supply capacity: 100,000 square meters per month payment terms: L/C, D/P, D/P, T/T, MoneyGram Origin: Fujian China Package: bullet bag+carton+corner+carton...... -

window price philippines low sliding glass door panels

Material: Automotive Grade Float Glass usage: Commercial glass doors, medical, greenhouses, curtain walls, railings, imaging, lighting, bulletproof, displays structure: hard type: Energy-saving laminate After-sales service: Return and exchange, on-site inspection, online technical support, on-site..... -

Double-sided single-sided Low-e glass window heat insulation 4mm 5mm Tianjin door temperature double-sided low-E glass sun protection room Low-E glass

Packaging Details: wooden box usage: Industry, Decoration, Greenhouse, Curtain Wall, Railing, Bulletproof, Instrumentation price: 0.99-1.5 USD/mm/square meter Origin: Hebei china MOQ: 1 fcl(1000 sqm/sqm) port: Tianjin, Qingdao, Dalian payment terms: L/C, D/P, D/P size: 1830x2440mm, 2140x3300mm,...... -

Manufacturer Direct Insulation Architectural Glass Crystal Solid Tempered Low-E Blue Glass Home House Decoration

shape: flat usage: decorate Warranty: 5 years, 5 years Material: Glass payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram product name: Low-E blue glass color: other structure: solid model: 9 brand: Yao Yu Glass Project solution ability: others thickness: 3mm-20mm After-sales service:...... -

Solar Control Gray Reflective Coated Glass

structure: hard brand: leader glass Package preview: Origin: Shandong China Supply capacity: 20000 square meters per day Glass color: Silver, Bronze, Gold Bronze, Euro Grey, Dark Grey, F-Green, Ford Blue Certification: ISO9001-2002, EU certification application: Yards, leisure facilities,......