Solve the space limitation of new LED cold forging square copper needle fin heat sink

- $3.50 /piece

- 1 piece

- Shenzhen Like Hardware Electronics Co., Ltd.

- Guangdong, China

- Mr Rico Huang

Product Detail

| Material: | C1020 | color: | the gold |

| port: | Shenzhen | type: | heat sink |

| brand: | like | Surface treatment: | passivation |

| shape: | rectangle, square | Body material: | copper |

| strength: | 5-10W | payment terms: | L/C, Western Union, T/T, Paypal, Alipay |

| thickness: | 3-5mm | Supply capacity: | 3000pcs led cold forged square copper pin fin radiator per day |

| Protection class: | IP65 | product name: | New type led cold forging square copper pin fin radiator |

| Lighting Solutions Services: | Lighting and circuit design, automatic CAD layout, project installation | Warranty (year): | 5 |

| Certification: | ROHS Directive | Key words: | Copper Pin Fin Heat Sink |

| Packaging Details: | Our packaging advantages: 1) Internal blister tray; 2) External carton packaging. | Origin: | Guangdong, China |

| body color: | the gold | application: | to lead |

| process: | cold forging | Surface treatment: | passivation |

hot product

Product Details

feature:

• Rugged one-piece forged aluminum construction for maximum thermal conductivity.

• Pin-fin design maximizes surface area and provides all-around cooling to eliminate concerns about heatsink orientation (unlike linear extrusions).

• Precision machined flat base ensures consistent contact between heat sink, interface and LED substrate for maximum

Spread the heat.

• Standard 3mm base thickness allows for the full recommended depth of the mounting hole.

• Precision machined flat base ensures consistent contact between heat sink, interface and LED substrate for maximum

Spread the heat.

• Standard 3mm base thickness allows for the full recommended depth of the mounting hole.

Specification

product number | LK-L38-W38-H30-T3-0102 | ||||||

length | 38mm (1.496inch) | ||||||

width | 38mm (1.496inch) | ||||||

high | 30mm (1.818inch) | ||||||

thickness | 3mm (0.118incg) | ||||||

weight | 0.07 kg | ||||||

strength | 20W | ||||||

thermal resistance | 0.59℃/Watt | ||||||

Material | AL1070, AL1050 | ||||||

processing | Cold Forging, CNC, Drilling, Threading | ||||||

Finish | anodizing, electrophoresis | ||||||

color | black, silver, any color, multicolor | ||||||

application | LED lights, track lights, high pole lights, high bay lights | ||||||

detailed drawing

Why choose cold forging process:

Radiators generally have three processing techniques: die-casting, extrusion and cold forging. Because the material is different, the heat dissipation coefficient obtained is also different. Under the same size condition, the power supported by the cold forging radiator is 2.35 times that of the die casting and 1.45 times that of the extruded profile.That is, when the user wants

For the same power, the cold forged radiator will be smaller and lighter. The risk of hoisting is also reduced. Shipping costs are also lower.

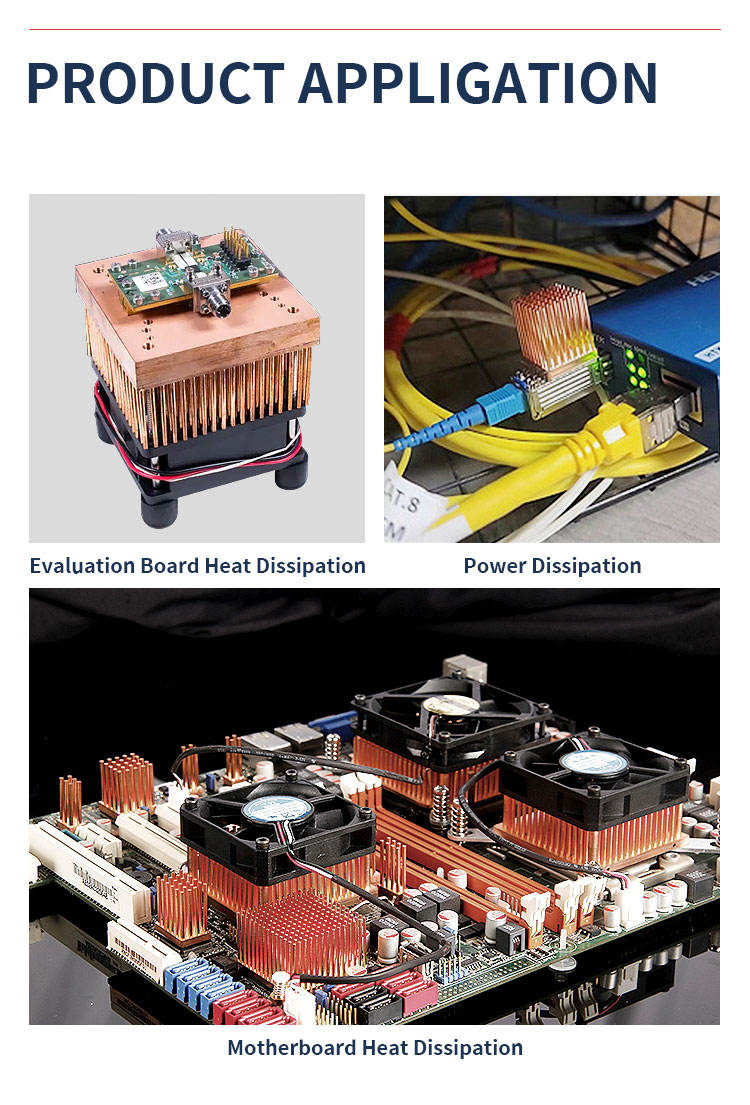

application

VIEW MORE

Related Products

-

High performance square LED light radiator 100(W)*36(H)*100(L)mm LED application aluminum radiator

Product Description Product name Aluminum radiator 100(W)*36(H)*100(L)mm Material AL 6063 T5 Detailed dimensions As shown below, or according to customized design Maximum aspect ratio (Fin height/fin gap) The 800- to 6000-ton extrusion machine uses the most advanced technology to extrude radiators..... -

Custom Liquid Cooled Plates Custom High Power Water Chiller System

Lighting Solutions Services: Heat dissipation Product weight (kg): 0.2 Minimum order quantity: 1 Place of origin: Guangdong, China Luminous efficiency (lm/w): 150 Surface finish: Antioxidant coating Surface treatment: anti-oxidation tolerant: 0.01 mm Package preview: Supply capacity: 100,000 pieces.... -

Extruded aluminum heater for LED light 111.5(W)*76(H)*110(L)mm

Product weight (kg): 0.6 asphalt: 8.46mm shape: square Lighting Solutions Services: Automatic CAD layout Place of origin: China Surface treatment: (black) anodized, (black) anodized brand: Huajie process: Extrusion + CNC Sales unit: Single product Standard mold quantity: 30,000+ sets Gross weight...... -

Stadium Stadium Waterproof IP65 100W Street Light LED LED Street Light LED Outdoor Pole Street Light Street Light

port: Zhuhai Port Body material: aluminum alloy Package preview: Warranty period (years): 10 years Supply capacity: 1 acre per day payment terms: MoneyGram Product weight (kg): 5 body color: silver Protection class: IP65 type: heat sink brand: Ah Hui shape: round Packaging Details: carton Luminous..... -

Die Casting Aluminum LED Bulb Housing SKD Bulb Fittings T Bulb Parts

product name: Light bulb process: die casting brand: OEM/ODM thing: Aluminum LED housing LED light source: SMD 2835 Surface treatment: painting Origin: Guangdong, China Packaging Details: carton application: LED bulb housing Serve: Custom OEM usage: LED heat sink aluminum payment terms: T/T,...... -

Aluminum Die Casting LED Street Light Enclosure LED Flood Light Enclosure Kit LED High Bay Enclosure

shape: square Supply capacity: 30000 pieces per month type: heat sink Warranty period (years): 2 years product name: led street light housing Origin: China Body material: aluminum Lighting Solutions Services: Lighting and circuit design, on-site measurement, engineering installation brand: An Erhui.... -

40w Diameter 133mm Height 40mm Black Anodized Round LED Lamp Pin Fin Aluminum Cooler Radiator with Axial Fan

Origin: Guangdong, China Lighting Solutions Services: Lighting and circuit design, automatic CAD layout, engineering installation Body material: aluminum usage: India Package preview: shape: round Key Features: machine work Color Finish: the color you want Protection class: IP67 level thing:...... -

OEM manufacture Aluminum Cooling Heat Sink Chip Heat Sink Cooler for LED Power Transistor Electronic Heat Sink Chip

Origin: China Warranty (year): 1 year process: Extrusion+CNC Body material: aluminum Material: aluminum alloy MOQ: 500 Certification: ce application: LED lighting radiator brand: OEM production Serve: OEM\ODM product name: radiator squeeze radiator Packaging Details: 1. Inner packing: PP bag,...... -

China radiator manufacturer custom Spplayed CXB3590 Pin Fin Heat Sink Spplayed Pin Heatsink

type: heat sink shape: round Packaging Details: in a carton. bulk in pallets Origin: Guangdong, China Supply capacity: 50000 pieces per month product name: cxb3590 radiator Warranty (year): 5 payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Processing technology: Anodizing color: Require.... -

Custom High Power 500W Copper Tube Welded Heat Sink for LED Lighting

process: stamping, welding, bending, stamping, welding, bending usage: led ; light cooling Supply capacity: 100000 pieces per month Body material: aluminum alloy Lighting Solutions Services: Lighting and circuit design, DIALux evo layout, LitePro DLX layout, Agi32 layout, auto CAD layout, Onsite......