OA-500 office building bare steel mesh raised floor price

-

$3.75 / 2 - 99 pieces

$3.62 / 100 - 199 pieces

$3.50 / 200 - 499 pieces

$3.37 / >=500 pieces - 2 pieces

- Xi'an Zhihui Computer Room Equipment Co., Ltd.

- Shaanxi, China

- Mr Quan

Product Detail

| Unsupported height: | Negotiable | Floor Thickness: | 28 mm |

| application: | office building | design style: | modern |

| color: | Black | Uniform load: | ≥9760 N/㎡ |

| After-sales service: | Online technical support, free spare parts, online training | Warranty: | 1 year |

| Packaging Details: | Two pieces in one carton, 60 pieces in one wooden box | brand: | Wisdom |

| Package preview: | Accessories: | with brackets, beams and screws | |

| port: | Shanghai, Ningbo, Tianjin | Certificate: | ISO9001+OHSAS+GB/T28001-2011+ISO14001 |

| Project solution ability: | Project overall solution, cross-category integration, others | usage: | OA500-450 type 5A office building, office building decoration |

| model: | OA500-450 | Supply capacity: | 1,500,000 square meters per year |

| final load: | ≥5880N | Concentrated load: | LB≥440, N≥1960, KG≥200 |

| payment terms: | L/C, D/P, T/T, Western Union, Trade Assurance | size: | 500mm*500mm*28mm |

| place of origin; place of origin: | Shaanxi, China | Material: | Steel, Advanced Foamed Cement |

OA-500 office building bare steel mesh raised floor price

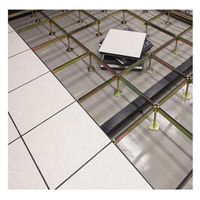

OA 500 mesh floor

-Material: SPCC steel plate; ST14 steel plate; foam cement;

- Processing:stretching, spot welding,

- Processing:stretching, spot welding,

Phosphating, plastic spraying.

-The cavity is filled with high-grade foamed cement.

-Four corners with corner locks.

feature

- All steel structure, strong bearing capacity

-Excellent fire resistance

- Good dimensional accuracy, interchangeable panels

Advantage

Specializing in the production of anti-static floor for more than 30 years with good quality-fireproof

- sound insulation

- Manufactured with high precision

- easy to install

- good interchangeability

- The installation height can be adjusted arbitrarily

Numbering. | National standard | Specification (mm) |

OA500-450 | HDG.500.28.CQ.D.OA | 500X500X28 |

OA500-650 | HDG.500.28.QDQA | 500X500X28 |

OA500-1000 | HDG.500.28.BDOA | 500X500X28 |

OA500-1250 | HDG.500.28.ZDOA | 500X500X28 |

Item No.: OA500-450

National standard: HDG.500.28.CQ.D.OA

Concentrated load: LB≥440; No≥1960; kg≥200

Ultimate load: 5880 N

Uniform load: ≥9720N/㎡

Item No.: OA500-650

National standard:HDG.500.28.QDQA

Concentrated load: LB≥662; N≥2950; kg≥301

Ultimate load: 8850 N

Uniform load: ≥12500N/㎡

Concentrated load: LB≥662; N≥2950; kg≥301

Ultimate load: 8850 N

Uniform load: ≥12500N/㎡

Item No.: OA500-1000

National standard:HDG.500.28.BDOA

Concentrated load: LB≥1000; N≥4450; kg≥450

Ultimate load: 13350 N

Uniform load: ≥23000 N/㎡

National standard:HDG.500.28.BDOA

Concentrated load: LB≥1000; N≥4450; kg≥450

Ultimate load: 13350 N

Uniform load: ≥23000 N/㎡

Item No.: OA500-1250

National standard: HDG.500.28.ZDOA

Concentrated load: LB≥1250; N≥5560; kg≥567

Ultimate load: 16680 N

Uniform load: ≥33000 N/㎡

National standard: HDG.500.28.ZDOA

Concentrated load: LB≥1250; N≥5560; kg≥567

Ultimate load: 16680 N

Uniform load: ≥33000 N/㎡

application

Due to the characteristics of the network floor, it overcomes the defects of the existing floor cable scheme, and well adapts to the requirements of fast network changes, multiple access ports, writing floor heights, anti-static, and flame retardant. Therefore, it is very suitable for large office buildings, computer rooms, intelligent buildings, securities halls, government agencies, financial institutions, scientific research institutions, radio and television center sites, post and telecommunications, communications, telecommunications, education, advertising printing, conference centers, media production, electricity, transportation, Business website, the application of which will promote the further development of high-tech technology

Construction points

1. The laying of the mesh floor is the last process of interior decoration, the ceiling must be completed first, and then the mesh floor is laid. The mesh floor of the open wire channel can be laid together with the wiring.

2. The mesh floor can be sawed, and the floor can be laid on the pillars, corners and surfaces of the room. Because there are many cables drawn from the electric box, a section of busbar steel cover plate evacuation cables should be laid when entering the mesh floor.

3. The outlets in the net floor can be connected to the junction box (box with strong and weak current sockets) or the strong and weak current sockets fixed on the aluminum buckle plate under the office partition or on the furniture. When furniture is changed, the junction box socket can be moved to a new location.

4. If grounding wires for equipment grounding and computer grounding are required, the grounding wire of the main grounding electrode can be arranged in the wire slot

maintenance and repair

1 During the handling process, the net floor should avoid violent collision and extrusion, so as not to cause damage to the net floor.

2 Avoid strong corrosive liquids or gases from contacting the floor, so as not to cause damage to the clean floor.

3 During use of the mesh floor, do not place heavy objects that exceed the floor's bearing capacity directly on the mesh floor.

4 Try to avoid strong sunlight shining on the floor for a long time, so as to avoid the aging and deterioration of the floor and affect the service life of the floor

5 In the process of cleaning and maintaining the floor, try to use volatile cleaners to clean the surface of the floor, and it is strictly forbidden to use iron brushes and other hard objects to clean the floor

floor display

our company

In 1990, we produced the first anti-static floor. Xi'an Zhihui Computer Room Equipment Co., Ltd. is a professional manufacturer engaged in the design, research and development, production, sales and installation of various anti-static raised floors, such as anti-static steel structure activities in computer rooms Floor, OA mesh floor, clean room conductive raised floor, airflow raised floor, calcium sulfate raised floor, wood core board, aluminum anti-static raised floor, etc.

We have advanced production equipment, mature production technology, strong strengthTechnical research, product development, mass production, sales, installation and other teams;

Our company strength:

A: Registered capital: RMB 67 million

B: Factory area: covers an area of more than 40 acres

C: Production line: 10D: Product categories: more than 100 kinds

E: Annual production capacity: more than 1.5 million square meters

our certificate

We have passed ISO9001, ISO14001, OHSAA8001 certification.

Produced in strict accordance with SJ/T10796-2001 standard,Comply with CISCA, CE, MOB international standard certification

Our product application

A. Computer center; Communication center; Data center; Radio and television transmission center; Power control and dispatch center; Microwave communication station; Satellite ground station; Mobile center;

B. Electronic and optical equipment production workshops; hospital operating rooms; anesthesia rooms; electronic imaging inspection rooms; other places sensitive to static electricity.C. Inflammable and explosive places such as military industry and petrochemical industry.

D Civic center; star hotel; smart office and other high-end places

our export market

We have stable quality and beautiful appearance; exported to Japan, South Korea, Singapore, Malaysia, the United States, the Middle East, Europe and other countries and regions; long-term service in domestic computer room decoration engineering companies, integrators, purification engineering companies, real estate developers, Won the praise of the majority of customers.

our production line

It has more than ten floor production lines such as calcium sulfate floor production line and all-steel alloy floor production line; aluminum alloy floor production line; net floor production line, etc. We produce strictly according to SJ/T10796-2001 standard.

FAQ

What is your packing condition?

Usually, we pack 2pcs flooring in one carton, and then pack 60pcs in one wooden pallet for shipping container.

What are your payment terms?

30% deposit should be paid before mass production, 70% balance should be paid before shipment

What are your terms of delivery?

Usually, we pack 2pcs flooring in one carton, and then pack 60pcs in one wooden pallet for shipping container.

What are your payment terms?

30% deposit should be paid before mass production, 70% balance should be paid before shipment

What are your terms of delivery?

EXW, FOB, CIF, CFR at Shanghai port, Tianjin port and other ports in China

How about your delivery time?

Products in stock: normal items, it will take 1-2 days after receiving your deposit.

Products in stock: normal items, it will take 1-2 days after receiving your deposit.

Customized products: depends on the quantity you need, generally 10-15 days after receiving your advance payment, large quantity needs to be negotiated

Do you test all your goods before delivery?

Our QC test all goods at production time and before shipment

Can you provide samples?

Yes, we can provide one free sample, two samples, you only need to pay the shipping cost

What certification do you have?

ISO14001:2015, OHSAS 18001:2007, ISO9001:2015

maintenance and use

The room temperature for laying the anti-static floor is controlled at 15°C-35°C; the humidity is controlled at 45%-75%RH; if the computer room is in a high temperature or low humidity state for a long time, the floor surface will peel off or break.

1. It is forbidden to use sharp tools to operate directly on the floor to prevent damage to the anti-static performance and aesthetics of the surface;

2. During use, it is strictly forbidden for personnel to jump directly from a height to the floor.

3. When moving the equipment on the floor, it is strictly forbidden to push the equipment directly on the board to scratch the floor. The correct way is to lift the equipment for handling

4. When there is heavy equipment in the machine room, the equipment should be placed directly on the ground base, not directly on the floor, causing long-term load-bearing deformation of the floor;

5. When maintaining the equipment under the floor, the floor is sucked up by the plate lifter for operation. It is forbidden to use sharp tools for brutal disassembly.

6. For maintenance, use a vacuum cleaner or a semi-dry mop to keep the floor clean, especially do not spill liquid on the floor.

7. The computer room is suitable for humidification in autumn and winter, and the floor surface is regularly maintained with anti-static wax to ensure the long-term use of the floor.

2. During use, it is strictly forbidden for personnel to jump directly from a height to the floor.

3. When moving the equipment on the floor, it is strictly forbidden to push the equipment directly on the board to scratch the floor. The correct way is to lift the equipment for handling

4. When there is heavy equipment in the machine room, the equipment should be placed directly on the ground base, not directly on the floor, causing long-term load-bearing deformation of the floor;

5. When maintaining the equipment under the floor, the floor is sucked up by the plate lifter for operation. It is forbidden to use sharp tools for brutal disassembly.

6. For maintenance, use a vacuum cleaner or a semi-dry mop to keep the floor clean, especially do not spill liquid on the floor.

7. The computer room is suitable for humidification in autumn and winter, and the floor surface is regularly maintained with anti-static wax to ensure the long-term use of the floor.

Precautions in USE

1. Site environmental requirements.

Temperature: 10-30°C

Relative humidity: RH 30-70%;

Temperature change rate: △Tw15℃/hour, or no condensation;

Vibration: no sustained vibration (source);

Chemical environment: no volatile substances, no highly corrosive substances

2. It is strictly forbidden to wash the surface of the elevated floor with water, and mop the floor with a wrung mop to prevent the surface of the elevated floor from peeling and the lower metal parts from scaling

3. Do not use hard objects (or sharp objects) to squeeze, hit, scratch, paint or paint plastic

4. When opening or installing the access floor, use a special panel lifter to handle it gently, and do not use hard pry iron.

5. Places with many people, such as corridors and entrances, should avoid overloading, otherwise the floor will be easily damaged.

6. For long-term heavy loads, when the weight of a support point of the machine is greater than 1/3 of the load-bearing level of the floor, the corresponding part of the floor should be supported by a column, otherwise the floor will be easily deformed.

7. After the floor is laid, there may be noise when walking, which is related to the floor and installation, and has nothing to do with the performance of the floor itself.

8. Do not use heavy objects that may damage the floor.

9. Do not modify the floor at will. Do not move the panel lifters while the panel lifters are sucking the floor to prevent them from falling on the floor

method. When shooting the floor, you should wear gloves, otherwise it will easily hurt your hands, and avoid direct sunlight, so as to avoid premature discoloration and aging of the finish layer.

10. Do not lay gas and water pipes under the floor.

Installation diagram

Contact information

E-mail: [email protected]

Whatsapp: 0086-13201712057

WeChat: 13201712057

Tel: 86-13201712057

WeChat: 13201712057

Tel: 86-13201712057

VIEW MORE

Related Products

-

Self-adhesive tiles reinforced vinyl flooring waterproof engineering plastic flooring wooden PVC flooring tiles

brand: Baolin size: 800*800mm design style: modern usage: Protective grounding Certificate: ISO14001, ISO9001 Fire-proof level: B1 product name: Stone pattern pvc floor application: A variety of applicable scenarios, a variety of applicable scenarios Supply capacity: 2,000,000 square meters per...... -

High Quality Data Center Floor Static Raised Floor Tiles Price

Concentrated load: LB≥440, N≥1960, KG≥200 design style: traditional payment terms: L/C, D/P, T/T, Western Union, Trade Assurance Floor Thickness: 35 mm brand: Wisdom final load: ≥5880N Accessories: with brackets, beams and screws Warranty: 1 year Origin: Shaanxi, China Packaging Details: 1 carton...... -

Best Price Self Adhesive Waterproof Luxury PVC Flooring Price Tile Vinyl Plank Plastic Flooring

Warranty: over 5 years product name: Stone pattern pvc floor brand: Baolin Origin: Jiangsu, China size: 800*800mm Finishing material: pvc Project Solution Capabilities: graphic design Function: waterproof Package preview: Supply capacity: 2,000,000 square meters per month port: Shanghai payment...... -

China online store low price high quality sealed custom size floor matching anti-static raised floor base price

color: silver or yellow Bearing: 3000 kg Supply capacity: 30000 pieces per week application: hotel After-sales service: Free spare parts, online technical support, on-site inspection, on-site installation, on-site training, return and exchange Packaging Details: Packaging Details: Normal Height:...... -

High Quality Raised Floor Air Conditioner Aluminum Perforated Raised Floors

Surface treatment: conductive epoxy After-sales service: Online technical support, free spare parts, others Packaging Details: 1. Panels are packed in pallets, bases are packed in cartons/pallets 2. A 20ft container can load 350-428 square meters of panels and accessories application: tidy up the...... -

China Factory Dustproof Durable Plastic Raised Floor System Waterproof Mero Raised Floor

Material: steel, wood, calcium sulfate, metal port: Shanghai, Changzhou, Ningbo, etc. model: 7001-8030 size: 590*590mm, 600*600mm, 610*610mm, customized Packaging Details: 1. A4 size and catalog samples are packed with bubble film and waterproof bag 2. The goods of one 20ft container are packed...... -

Data center raised floor system

After-sales service: Free spare parts, online technical support, on-site inspection, on-site installation, on-site training, return and exchange model: AS680/AS800/AS1000/AS1250/AS1500/AS2000 product material: steel, cement Package preview: Concentrated load: 2950N-5560N Supply capacity: 5000...... -

Wholesale factory indoor wooden bathroom self-adhesive sticker tile waterproof vinyl flooring pvc engineering plastic flooring

color: grey Fire-proof level: B1 application: Multiple applicable scenarios, Multiple applicable scenarios model: 1816 Packaging Details: Packed in cartons and pallets brand: Pauline Finishing material: plastic Material: pvc Certificate: ISO14001,ISO9001 port: Shanghai product name: Stone pattern...... -

Affordable fire rated raised floor panels, wooden raised floor for computer room in modern style

size: 590*590mm, 600*600mm, 610*610mm, customized design style: modern port: Wuhan Shanghai application: Apartments, computer centers, data centers, hospital operating rooms, workshops Metal Type: steel Project solution ability: others Material: pvc Origin: Jiangsu, China, China Product Thickness:..... -

Vinyl floor tile sticker self-adhesive plastic floor waterproof sheet pvc floor peel off tile

application: Multiple applicable scenarios, Multiple applicable scenarios Finishing material: ceramics product name: Self-adhesive PVC floor brand: Pauline Fire-proof level: B1 Function: waterproof product material: composite wood Packaging Details: Packed in cartons and pallets Origin: Jiangsu,......