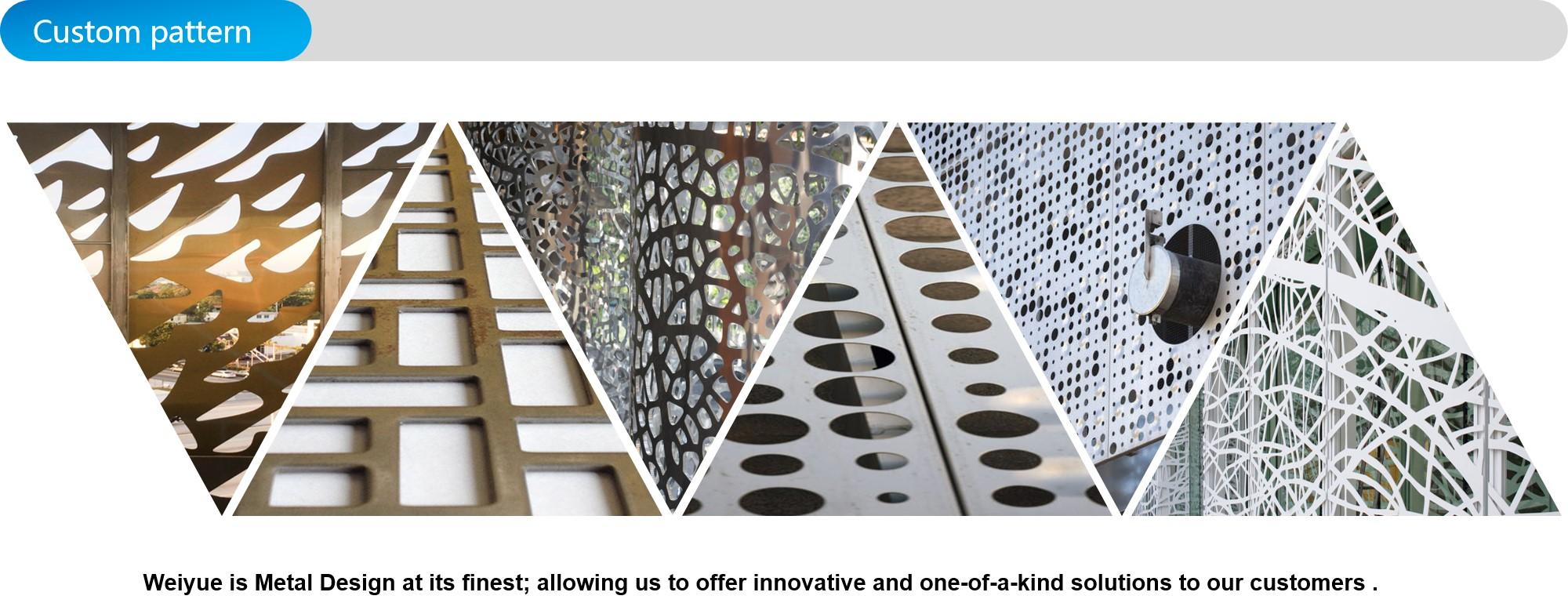

Aluminum perforated metal sheet for custom design decoration

-

$5.65 / 1 - 9 square meters

$3.33 / >=10 square meters - 1 square meter

- Hebei Weiyue Wire Mesh Products Co., Ltd.

- Hebei, China

- Mr David Jia

Product Detail

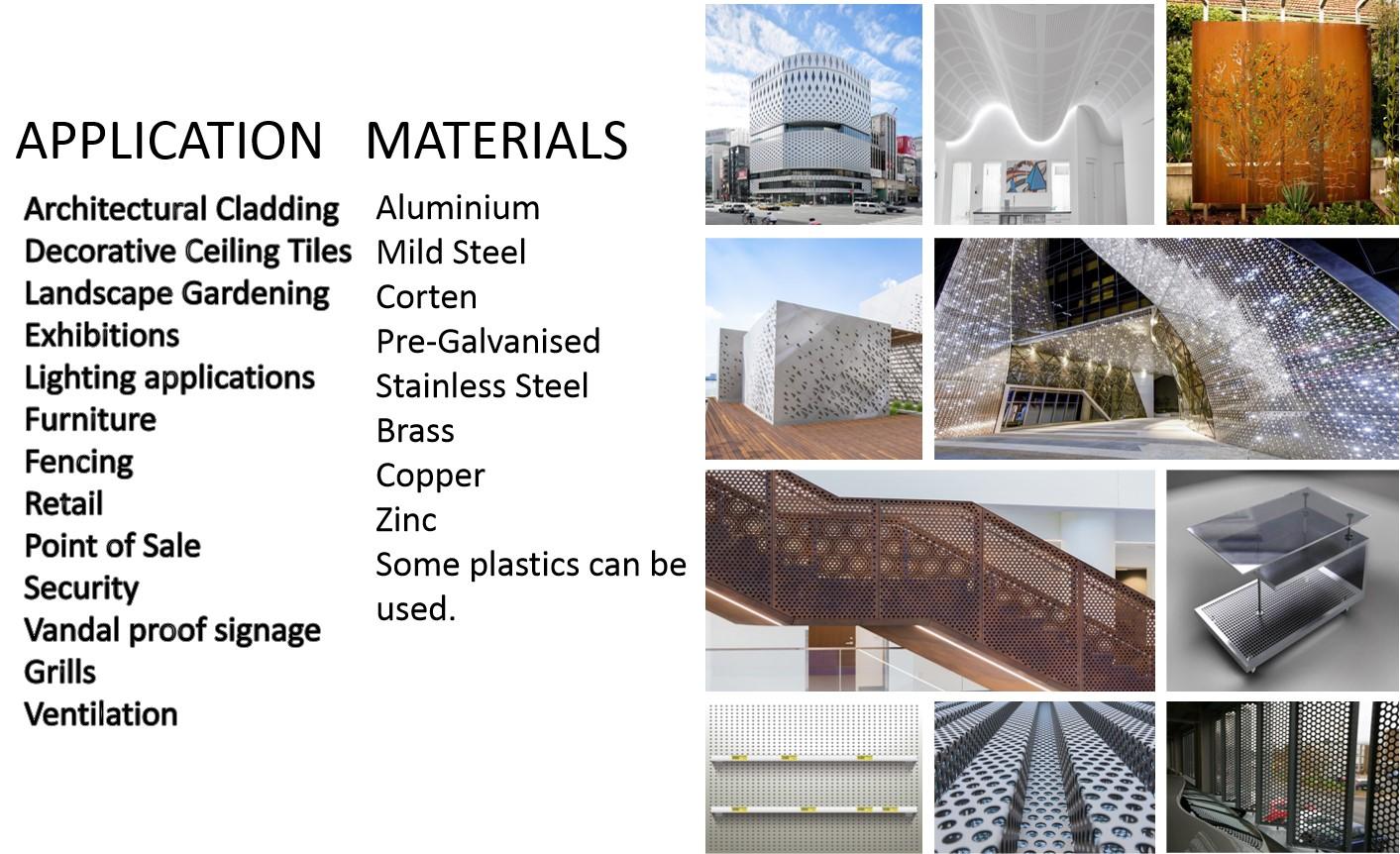

| Hole size: | 0.1-20mm | Warranty: | over 5 years |

| type: | curtain wall | Project Solution Capabilities: | Graphic design, 3D model design, overall project solution, cross-category integration |

| Material: | aluminum | Supply capacity: | 20,000 square meters per week |

| Packaging Details: | plastic film+wooden box | product name: | Aluminum siding |

| Surface treatment: | powder coating | model: | pregnant 056 |

| brand: | Wei Yue | Origin: | Hebei china |

| design style: | modern | application: | Building exterior walls, supermarkets |

| port: | Tianjin | length: | 10-30000mm |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | design: | Custom Aluminum Wall Panels |

| After-sales service: | Online technical support, on-site installation, on-site training, on-site inspection, free spare parts, return and exchange | Hole shape: | Square hole. Round hole |

| normal width: | 1220mm, 1250mm, 1500mm, 1570mm | thickness: | 0.1-10mm |

| Package preview: |

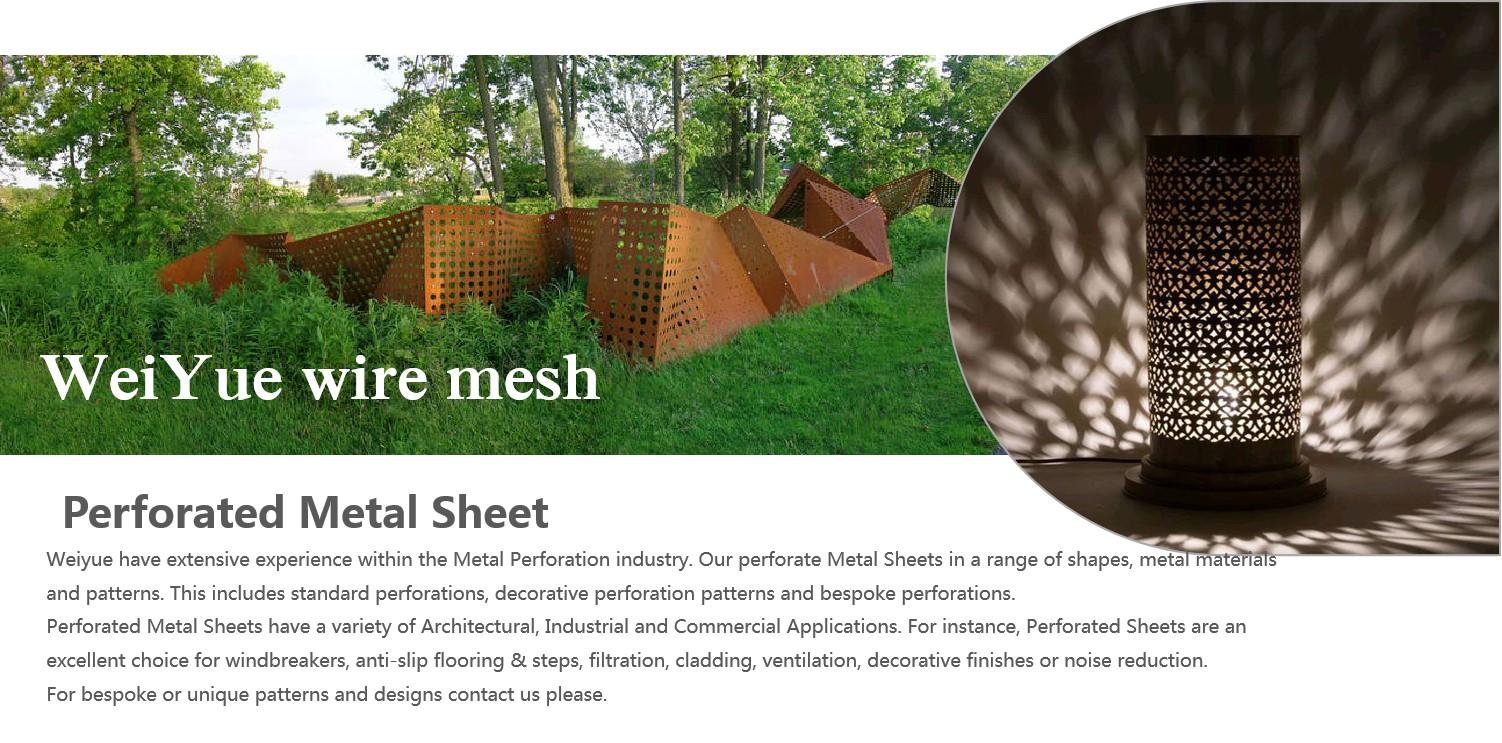

Product Description

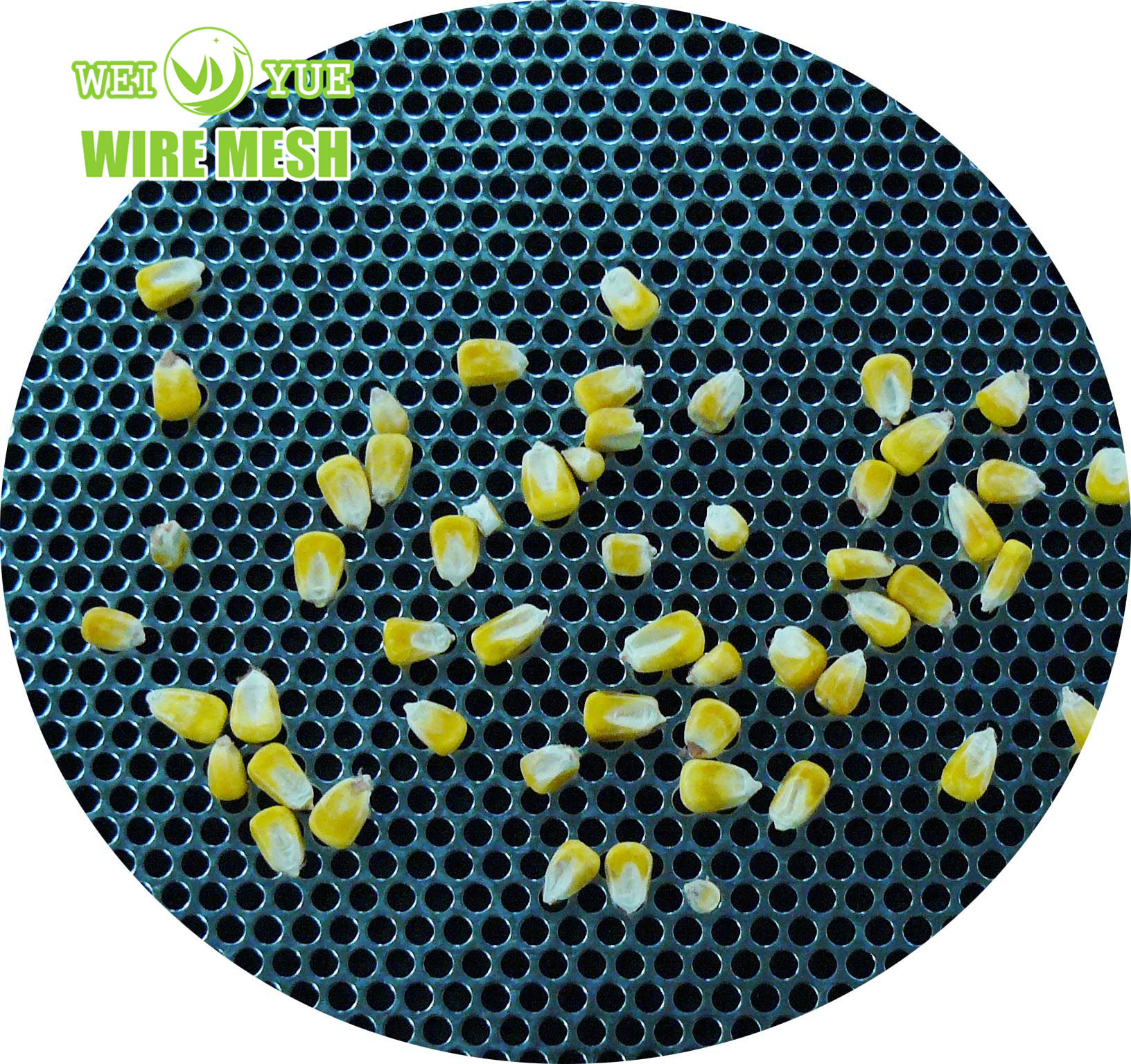

We have some round punched sheets in stock, the size is 1m x 2m,

Please contact me for more information.

Specification

our products | perforated metal mesh |

size | 1) Thickness: 0.3mm-12mm 2) Mesh length: 1.8m - 2.44m 3) Mesh width: 0.8m - 1.22m 4) Perforation area percentage: from 7% to 83% |

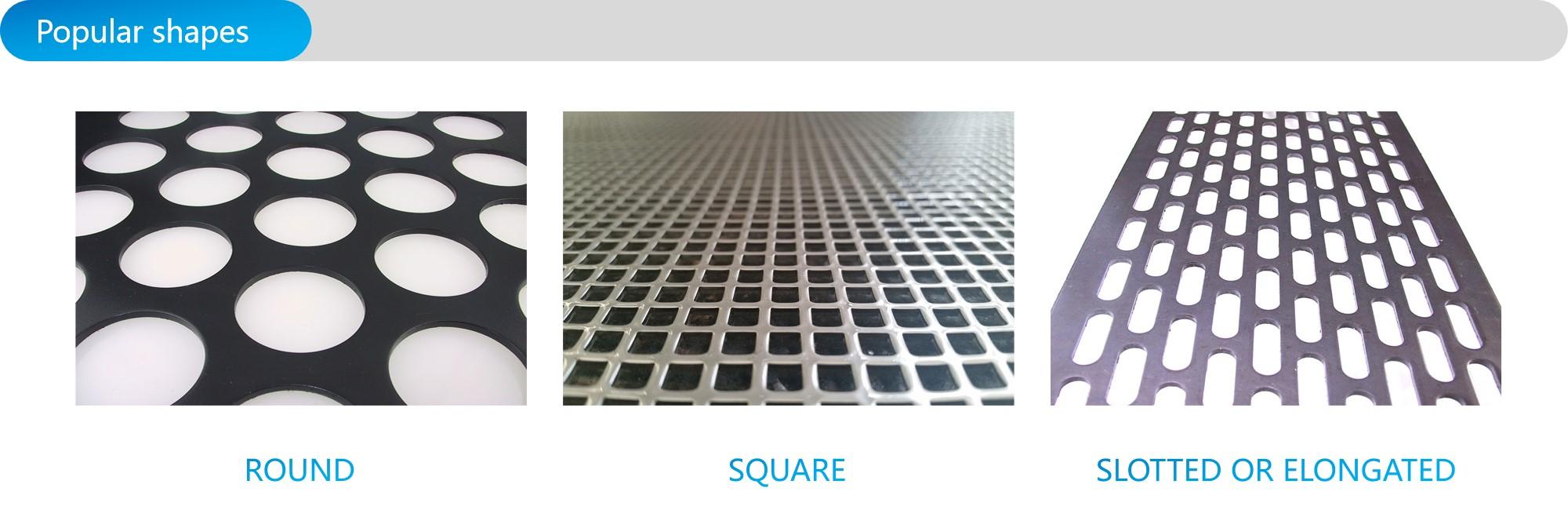

hole form | Rhombus, circle, square, triangle, hexagon, etc. |

surface treatment | Electro-galvanizing, hot-dip galvanizing, PVC coating, oxidation treatment, etc. |

feature | Corrosion resistance, aging resistance, durability, etc. |

Package | 1. LCL: packed with plastic film and put on pallet 2. FCL: naked 3. Other special packaging according to customer requirements. |

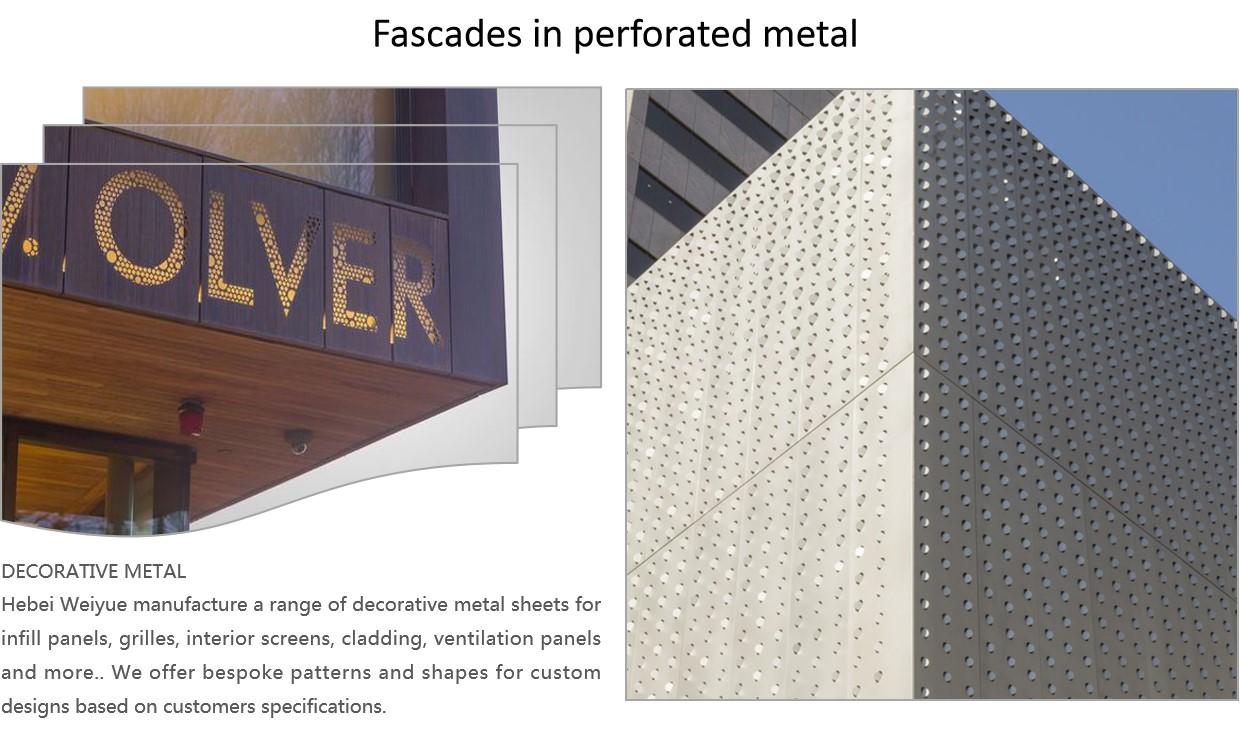

Finishing type

Metal finishing is a demanding task that can have a vital impact on the appearance and durability of the final product. For best results, we recommend that you rely on our finishing services. We offer various types:

ArnoldDidin

Anodizing is an electrolytic process used to increase the thickness of the naturally occurring oxide layer on many metal surfaces. Anodizing is commonly used with aluminum to take advantage of the inherent properties of aluminum oxide to create a hard, corrosion-resistant surface. Anodized aluminum has an attractive metallic sheen and can be clear or dyed in a variety of colours.

Clear Coat (Anodized)Clear anodizing is a process that creates a thin coating of aluminum oxide on aluminum metal without the use of dyes or pigments.Electrophoretic paintingElectrocoating is an electroplating or electrocoating process used to deposit paint or varnish coatings.GalvanizedThe most common method of galvanizing is the electrochemical deposition of zinc alloys. Because this process produces a relatively thin layer of galvanized coating, painting is often recommended for exterior applications to provide the best corrosion resistance.hot dip galvanizedThe part goes through a bath of molten zinc, which provides a thicker coating of zinc at a slightly higher cost than electrogalvanizing. Hot-dip galvanizing produces a characteristic crystalline pattern or "spangle" on the surface.draw gripGalvanized steel is dipped in a phosphate bath to provide additional corrosion protection and improve paint adhesion.paint lockGalvanized steel has a galvanized layer that is electro-deposited and then chemically treated to improve paint or powder coat adhesion.platingElectroplating refers to a series of processes that deposit a coating of one metal on the surface of another metal. Plating materials can be selected for their aesthetics, corrosion resistance, hardness, and various other purposes. Such as gold, silver, chromium, zinc, tin, cadmium, etc. Plating techniques also vary and include electroplating and electroless plating methods. Please contact us to discuss plating materials and methods suitable for your project.powder coatingPowder coating is an electrostatic process used to apply dry powdered materials such as polyester, polyurethane or epoxy. The parts are then heat cured, allowing the materials to flow together and create the final finish. Powder coating is usually thicker and more durable than paint, but can be slightly more expensive depending on the project. Available in a variety of colors. Large sheets and coils, corrugated parts, finished parts and even special designs - Precision Perforation can apply virtually any finish to perforated parts as long as we determine that the finish is suitable for the material. Contact us to discuss your finishing ideas and questions.

Our culture

product display

VIEW MORE

Related Products

-

Gold Colorful Processing Custom Aluminum Alloy Plate Asset Marking Plate 0.5 1mm Zero Cut Anodized Aluminum Plate

Project solution capabilities: Graphic design, 3D model design, overall project solutions, others Gross weight of single piece: 0.500kg Sales unit: Single product Place of origin: Guangdong, China Warranty: not any type: curtain wall Packaging details: wooden box brand: Dixuan model: 5052 design...... -

Exterior wall aluminum veneer aluminum veneer

port: Shanghai, Ningbo, etc. application: External design style: modern Place of origin: China Shanghai Package preview: Warranty: life payment terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram brand: alder dream After-sales service: Online technical support Project solution capabilities: graphic.... -

Sample Ventilated Exteriors Terracotta Wall Panels Clay Panels Rain Curtains Terracotta Cladding Available at Factory Prices

model: 20mm Single pack size: 45X10X2 cm Packaging details: wooden box Project solution capabilities: Graphic design, 3D model design, cross-category integration type: curtain wall Fire protection: usable Sales unit: Single product Gross weight per piece: 1.800kg brand: snails application: office...... -

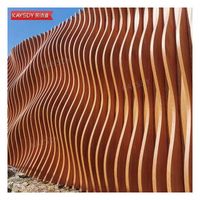

Modern office building decoration materials exterior wall curtain wall indoor and outdoor 3D wave wall panel aluminum sound insulation wall panel

Origin: Guangdong, China Warranty: over 5 years model: KSD605 After-sales service: online technical support product name: Exterior metal aluminum veneer wall panel usage: building exterior decoration type: curtain wall Packaging Details: Standard export carton shape:...... -

PANELTEK full sale Tile cladding for residential facades with bricks

Origin: Jiangsu, China port: Shanghai brand: panden Function: heat insulation waterproof fireproof usage: facade curtain wall product name: Wall decoration integral sale brick cladding application: building exterior, school Packaging Details: 1. Carton packaging 2. Wooden box packaging 3. Fumigated.... -

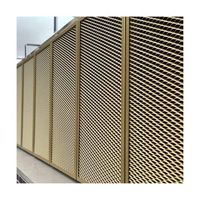

Aluminum Expanded Mesh for Building Facade

port: Tianjin application: apartment Warranty: over 5 years Supply capacity: 10000 square meters per week Packaging Details: - Tarps in pallets - Waterproof paper in wooden boxes - Cartons - Woven bags in rolls - Bulk or bundles model: ALD-015 Material: aluminum Package preview: Hole shape: diamond.... -

Wholesale Price IGU Unit Insulating Low-e Glass Curtain Wall, Tempered Offilne Coated Low-e Insulating Glass Curtain Wall

US certification: US Consumer Product Safety Commission 16 CFR 1201, ASTM C 1172-09 Project solution ability: Graphic design, overall project solution, others application: hotel Packaging Details: Wholesale Price Glass Manufacturer/Glass Block/Tempered Glass Origin: Shandong China Edge processing:..... -

Wood grain facade steel plate Aluminum corrugated facade curtain wall panel

Function: decorate Supply capacity: 5000 pieces per month Surface treatment: powder-coated PVDF painted port: Shanghai, Qingdao, Shenzhen, Tianjin, Guangzhou, etc. application: Building/hotel/villa/shopping mall/airport etc., hotel style: modern/luxury/traditional Material: Aluminum/Steel/Acrylic...... -

Wall Cladding Aluminum Perforated Curtain Modern Decor Wall Cladding

Packaging Details: Export special wooden box payment terms: wire transfer model: wall system Material: aluminum color: color type: curtain wall Project solution ability: Graphic design, graphic design, 3D model design, overall project solution, cross-category integration, others, CAD Origin:...... -

Whimsy Design Aluminum Facade Cladding Perforated Laser Cut

Package preview: payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Key words: aluminum perforated facade panel Surface treatment: Polyethylene, polyvinylidene fluoride width: ≤2000mm Supply capacity: 800,000 square meters per month After-sales service: Online technical support, on-site......