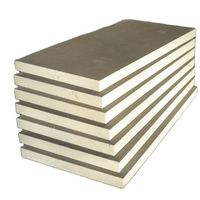

Lightweight 1200 degrees Celsius environmentally friendly vermiculite fireproof board ventilation duct fireproof board

-

$30.00 / 100 - 499 square meters

$28.00 / >=500 square meters - 100 square meters

- Shenzhen Bluewind Vermiculite Products Co., Ltd.

- Guangdong, China

- Mr Yusol Cheng

Product Detail

| Fire resistance time: | 2 hours | Supply capacity: | 2000 square meters per month |

| Material: | Silver vermiculite, diatomaceous earth | payment terms: | L/C, Western Union, D/P, T/T |

| After-sales service: | On-site installation, returns and replacements | Warranty: | 3 years |

| Selling point: | Environmental friendly | Project solution ability: | Graphic design, overall project solution |

| design style: | modern | Key words: | Fire insulation |

| brand: | blue wind | feature: | High fire temperature |

| color: | silver | type: | wall panel |

| port: | Tianjin | Core: | MDF |

| Packaging Details: | standard packing tray | thickness: | 12mm |

| product name: | Fire insulation vermiculite board | model: | BW-DMP900 |

| Origin: | Hebei china | application: | Home. Office. Hotel. Industry, Apartment |

| Package preview: | shape: | rectangle | |

| Function: | fire protection |

Description of Vermiculite Board

feature

High temperature resistance up to 1200℃;

High thermal shock resistance, can be used beside fire;

A1 non-flammability classification;

low thermal conductivity

Available in various densities from 400-1200 kgs/m3;

chemical resistance;

High mechanical strength;

Easy for secondary processing and processing, such as cutting, sawing, punching, etc.

For use under harsh conditions, vermiculite boards have excellent mechanical strength, good resistance to thermal spalling, and are highly resistant to chemical attack by volatile alkalis and some slags.

Stove application

For stove applications, light weight, good fire performance and thermal shock resistance are required. With all the benefits, vermiculite boards play an important role in stove applications, especially in wood stoves and pellet stoves. And our durable vermiculite board lasts longer and resists bending and pinching from uneven heating over time, making your stove last longer and less hassle to replace.

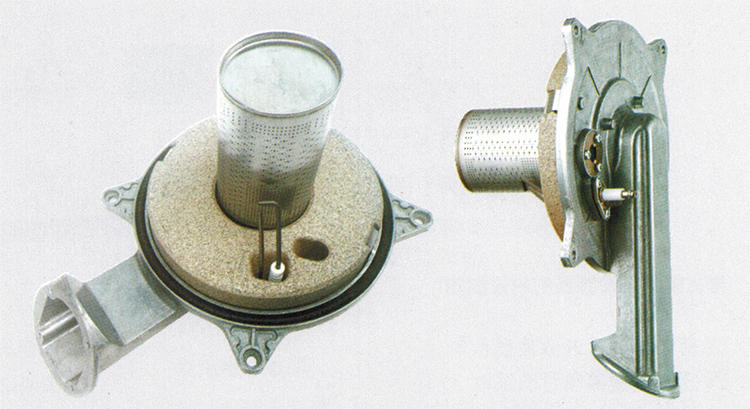

thermal battery

The heat chamber is the heart part of the condensing boiler, which determines the service life of the condensing boiler.The 1200℃ vermiculite board can withstand the environment of extremely rapid drying and water immersion; it has better performance than traditional ceramic fiber board.

condensing boiler

The ideal service life of a condensing boiler is about 12-15 years, and the heat battery at the heart determines whether it can achieve the ideal life. The use of high-quality vermiculite board can reduce the number of hot core replacements and reduce the worries of users.

Aluminum electrolytic cell

V-1100 and V-1200 are recommended for aluminum electrolytic cell applications. Their high strength and low thermal conductivity make them ideal for industrial applications. Various combinations of bulk density, insulation performance and compressive strength, V-1100(500), V-1100(1000) and V-1200 are usually selected for excellent performance in strength and heat insulation performance.Another important feature of aluminum pots is that the V-1100 and V-1200 series are not corroded by molten aluminum and are resistant to cryolite penetration and fluoride. It helps maintain battery life and keeps the aluminum electrolysis process running better.

Product parameters

physical parameters | ||||||

Density (kg/m3) | 700 | 800 | 900 | |||

maximum temperature | 1150°C | 1150°C | 1150°C | |||

strength | 4.5/2.0MPa | 5.5/2.1MPa | 6.2/2.2MPa | |||

linear shrinkage | 1% | 1% | 1% | |||

Heat Conduction. | ||||||

@200℃ | 0.14 W/m2 | 0.16 W/m² | 0.18 W/m² | |||

@ 400°C | 0.16W/square meter | 0.18 W/m² | 0.2 W/m² | |||

@600℃ | 0.18 W/m2 | 0.2 W/m² | 0.22 W/m² | |||

chemical parameters | ||||||

silica | 43-46% | 43-46% | 45-48% | |||

Aluminum oxide | 10-13% | 10-13% | 13-16% | |||

Ferric oxide | 4-6% | 4-6% | 4-6% | |||

Titanium dioxide | 1-2% | 1-2% | 1-2% | |||

magnesium oxide | 16-23% | 16-23% | 14-20% | |||

potassium oxide | 7-10% | 7-10% | 5-8% | |||

Na2O | 1-2% | 1-2% | 1-2% | |||

LOI @ 1000C | 4-6% | 4-6% | 3-5% | |||

Standard Sizes and Thicknesses | ||||||

1000*610mm | 10-60 mm thickness | 10-60 mm thickness | 10-60 mm thickness | |||

1200*1000 mm | 10-60 mm thickness | 10-60 mm thickness | 10-60 mm thickness | |||

Data are average results of tests performed under standard procedures and are subject to change.

Product packaging

production process

urgent

High pressure molded to desired shape

drying

Dries to release contained moisture and form a stable application

quality inspection

For each unit, we have one by one inspection to ensure the final use.

VIEW MORE

Related Products

-

Factory direct sales rock wool board building insulation waterproof rock mineral board rock wool board

shape: board/panel/piece/board/board Flammability level: Class A Thermal conductivity: 0.036-0.044w/mk Maximum operating temperature: Fireproof below 800℃ After-sales service: Online technical support density: 40-200kg/cubic meter application: Wall/sandwich panel/roof/fire door Place of origin:...... -

Vermiculite fireproof board A3 grade 1200kg/m3 10mm fireproof vermiculite board

Warranty: 1 year port: Tianjin Place of origin: Hebei china size: 1000*1000mm,2100x900mm Compressive strength: 0.690~4.90Mpa Linear Shrinkage: ≤1.50%(1000,3 hours) shape: board Packaging details: 25kg/bag. or as per your request type: Fireproof Materials Bending strength: 0.574~5.33Mpa model:...... -

White polyurethane fireproof board building special material heat insulation and sound absorption can be customized

width: 2.44m length: 1.22m Core material: Polyurethane port: Tianjin After-sales service: other product name: Polyurethane design style: modern density: 40-50 application: hotel Project Solution Capabilities: others shape: square Origin: Hebei china payment terms: L/C, Western Union, D/P, D/A, T/T,.... -

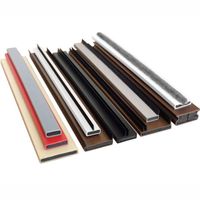

Low temperature sodium silicate expansion fireproof sealing strip

Core material: Sodium silicate/graphite shape: strip Performance: Flame retardant\fireproof\expansion model: BY-PCSW-1540 product name: Door and window fire seal Single pack size: 5X5X5 cm design style: industrial usage: self-adhesive Package preview: port: Tianjin\Qingdao\Shenzhen\Ningbo brand:...... -

Flexible Expanded Graphite Strips with Tape

Origin: Shandong China chemical composition: graphite, rubber aspect: as drawing or sample Material: eraser Packaging Details: Export standard packing, or as your request brand: fly size: as custom Name: Expansion Tape Warranty: 3 years port: Qingdao/Tianjin model: TC160 application: seal apartment.... -

Sell high-quality and high-price high-temperature-resistant fire-resistant mud flame-retardant materials

Corrosive: ≥7d Warranty: 5 years Package preview: brand: Run Ang Fire resistance: The fire resistance limit of the first-class fireproof sealing material is ≥180min Oil resistance: ≥3d? no swelling appearance: Plastic solid, with some softness application: office building Supply capacity: 100,000...... -

Fire protection package fire engineering pillow expansion site power cable shaft bridge block sandbag

brand: jewel heart model: Jewel Heart - 163 feature: flame retardant After-sales service: online technical support, other Project solution ability: others payment terms: L/C, Western Union, T/T Core: glass fiber type: 250,400,720 port: Tianjin harbor Warranty: 1 year Origin: Hebei china Material:...... -

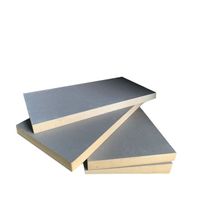

Lightweight insulating polyurethane foam board

size: custom size type: Fireproof sandwich panel feature: environmentally friendly Packaging Details: wooden pallet or bulk brand: Ruilian Material: fireproof material, metal application: office building port: Nanjing Shanghai Ningbo usage: fire insulation material design style: modern Key words:...... -

Steel structure fire retardant coating/high quality fire retardant coating for fire retardant coating

application: other port: Tianjin harbor Supply capacity: 2500 cubic meters per week Origin: Hebei china After-sales service: other Warranty: life Packaging Details: in the bag payment terms: wire transfer type: Firemark Project solution ability: others design style: Chinese brand: Wei Cheng product.... -

Good Quality High Density Rigid Insulation Board Polyisocyanurate Insulation Board Polyurethane Foam Insulation Wall Board

Project solution ability: overall project solution ability: fire insulation Warranty: 5 years usage: fire insulation material After-sales service: online technical support brand: Ruilian type: fire barrier Function: sound insulation payment terms: L/C, Western Union, D/A, T/T, MoneyGram Core:......