New Design Low Thermal Conductivity PU Foam Composite Vacuum Insulation Panel

- $3.00 / >=50 pieces

- 50 pieces

- Fujian Supertech Cold Chain Technology Co., Ltd.

- Fujian, China

- Mr Frank Hua

Product Detail

| Advantage: | excellent thermal stability | Warranty: | 1 year |

| shape: | custom shape | Package: | Carton + pallet |

| Package preview: | Project solution ability: | overall project solution | |

| port: | Xiamen | design style: | traditional |

| color: | silver | payment terms: | L/C, T/T |

| application: | Refrigerators, freezers, construction, logistics, warehouses | Supply capacity: | 100000 pieces per month |

| structure: | PU foam vacuum insulation panel | Processing: | presentable |

| Origin: | China | After-sales service: | online technical support |

| Size and shape: | custom made | MOQ: | 100 |

| sample: | usable | Packaging Details: | Packed with plastic film, then packed into cartons, then packed into wooden pallets |

product description

vacuum insulation panel

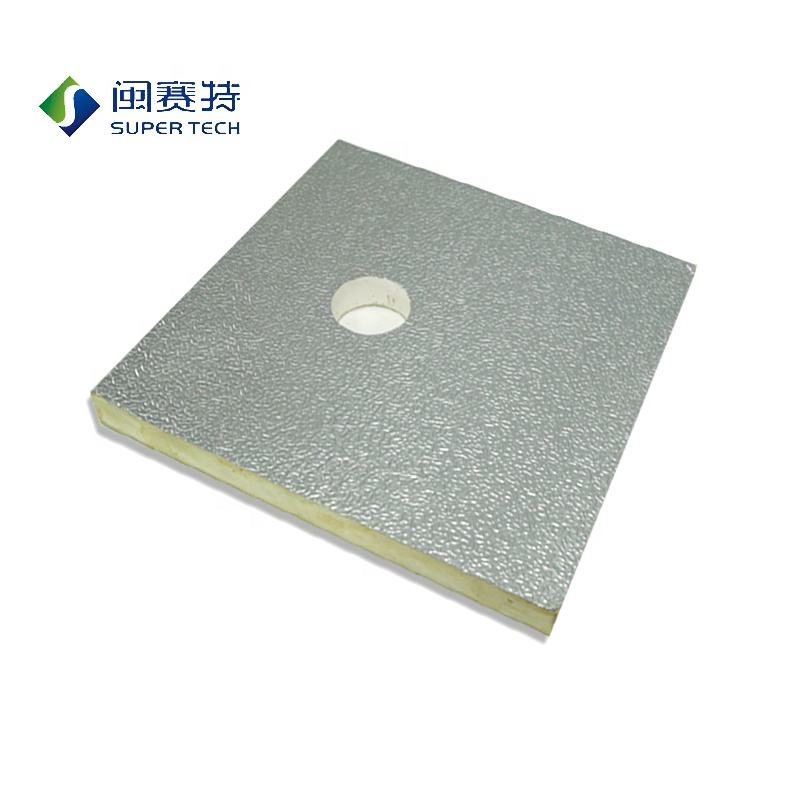

VIP is the abbreviation of Vacuum Insulation Panel in English; it is one of the thermal insulation materials, which is composed of core filling material and vacuum protection surface layer, which can effectively avoid air convection caused by heat transfer, so the thermal conductivity can be greatly reduced, less than 0.0025 w/mk, and does not contain any OD materials, it has the characteristics of environmental protection and energy saving, and is the most advanced high-efficiency thermal insulation material in the world.

Vacuum insulation panels can be widely used in chamfering thermal insulation systems of thermal insulation materials such as refrigerators, freezers, refrigerators, refrigerated containers, and ice cubes.

Fujian Chaoke New Material Co., Ltd. is the largest domestic manufacturer of vacuum insulation panels. Its products occupy a large share and are exported to Japan, South Korea, the United States, Europe and other countries.

Vacuum insulation panels can be widely used in chamfering thermal insulation systems of thermal insulation materials such as refrigerators, freezers, refrigerators, refrigerated containers, and ice cubes.

Fujian Chaoke New Material Co., Ltd. is the largest domestic manufacturer of vacuum insulation panels. Its products occupy a large share and are exported to Japan, South Korea, the United States, Europe and other countries.

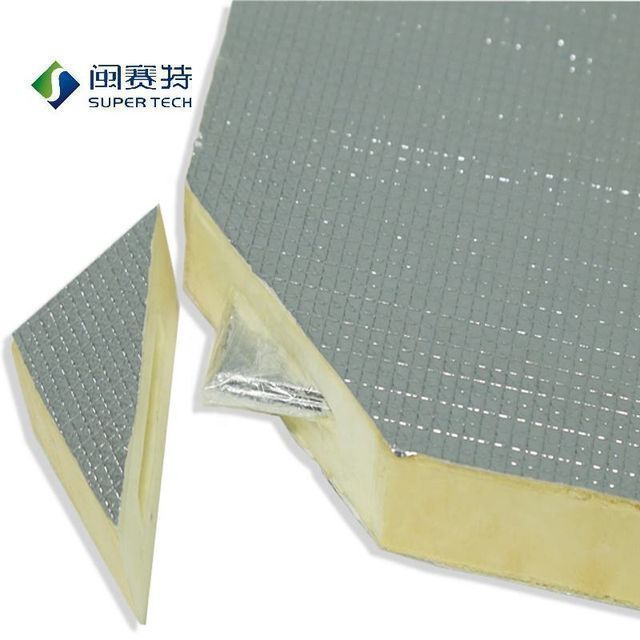

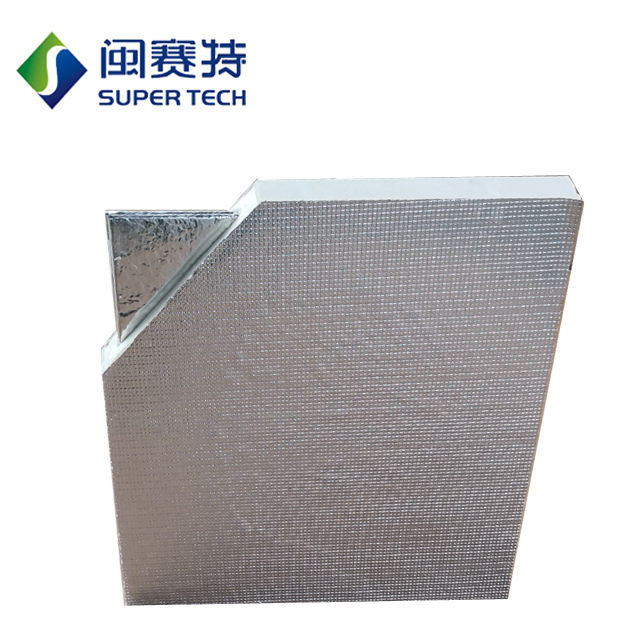

product components

1. Barrier film: high barrier multilayer composite film

Super Tech barrier film is laminated by multi-layer functional films, one of which is nano-film with excellent barrier properties and low thermal conductivity (effectively reducing thermal bridge effect).

2. Core material: high-performance glass fiber

3. Adsorbent: getter, CaO

Product parameters

length (mm) | width (mm) | thickness (mm) | Working temperature (℃) | Thermal conductivity (mW/(mK)) | Internal pressure (Pa) | External pressure (kPa) | Density (kg/m3) |

80~1800 | 80~800 | 4~40 | -70~80 | 1.5 | <10 | ≤200 | 240~300 |

Product details display

VIEW MORE

Related Products

-

TRUSUS 25mm thick aluminum foil insulation glass wool tube

width: 0.6m application: apartment Supply capacity: 1,000,000 acres per day After-sales service: Online technical support Certificate: International Organization for Standardization type: fiberglass cloth length: 7-30m brand: Terrassus Warranty: life Place of origin: China density: 24kg/cubic...... -

Thermal insulation raw material silica airgel powder is cheap

Density Kg/m3: 30-260 Particle size: 0.1-4.0 mm Surface properties: Hydrophobic Material: airgel Supply capacity: Annual output 60 tons Specific surface area: 600-800 application: building, building port: Shanghai design style: contemporary Thermal Conductivity: 0.016-0.021 W/kg model: ARG Origin:..... -

ASLONG Wavy Rubber Foam Sheet Wholesale, Roof Thermal Rubber Foam Sheet, Flame Retardant Egg Crate Shape Rubber Foam

After-sales service: online technical support, other Project Solution Capabilities: Graphic design, 3D model design, overall project solution Material: Rubber foam, aluminum foil, pressure sensitive adhesive, release paper, rubber foam roll Product Size: 8mm*1m*10m density: 50-55 kg/m3 type:...... -

Aluminum Car Heat Shield XPE Foam Insulation With Backing Self Adhesive For Car Sound Insulator Noise Control

Supply capacity: 50000 rolls per day 7 factories, more than 1000 employees port: Shenzhen, Tianjin, Shanghai, Ningbo Foam Color: blue, orange, green or customized brand: Xiamen Geological Survey Bureau Warranty: over 5 years Material: Aluminum foil + XPE/EPE foam + aluminum foil model: Xuzhou...... -

Material eps ICF foam block High quality construction foam board

payment terms: L/C, T/T, Western Union, MoneyGram Types of: other insulation materials product name: ICF block Shipping Details: 15-30 days after receiving the deposit Material: earnings per share port: Tianjin, Qingdao place of origin; place of origin: Hebei china Packaging Details: Bare packing,..... -

72-hour temperature protection Biodegradable environmental protection material incubator liner

Packaging Details: PE bag or carton product name: Insulated box lining place of origin; place of origin: Zhejiang, China Warranty: 5 years After-sales service: online technical support design style: modern Material: Aluminum foil, cotton paper, kraft paper model: QYALCB Supply capacity: 100000...... -

Knauf insulation facade partition FCB Knauf mineral wool partition board insulation board 2022

Project solution ability: other payment terms: wire transfer After-sales service: online technical support brand: Knauf product name: Knauf FCB035 Packaging Details: Each 40HC covers an area of 3732 square meters. Sturdy packaging and palletization. size: 600x1200mm density: 20kg/cubic meter...... -

cheap stone wool basalt insulation plate 100kg m3 50mm 100mm stone wool insulation price

width: 600-1200mm Package preview: brand: pear Thermal Conductivity: 0.044W/Micah design style: Basalt rock wool board insulation density: 50-200kg/m3 Material: Basalt, basalt rock wool board insulation thickness: 50-150mm Certificate: DNV CCS CE ABS ISO Supply capacity: 20,000 tons/year rock wool..... -

2022 Factory Supply Hydroponic 1.5 Inch Grow Cube Rock Wool Kit - For Agriculture Greenhouse Material

Warranty: not any Carton size: 520*520*420mm/20.4"*20.4"*16.5" size: 15*15*15cm type: Other insulation materials, rock wool products Number / Box: 20 Supply capacity: 10000 pieces per month Advantage: excellent thermal stability brand: TRILITE/OEM MOQ: 10 After-sales service: online technical......