New design WPC flooring with grass outdoor garden

- $2.20 / >=100 pieces

- 100 pieces

- Huzhou Kelai New Material Technology Co., Ltd.

- Zhejiang, China

- Ms Kelai Wood

Product Detail

| model: | GWD02 | port: | Shanghai Port/Ningbo Port |

| Packaging Details: | Tray strap + tray | size: | 300*300mm |

| brand: | Cole | product name: | Wpc Outdoor Decking diy tiles |

| type: | connect | design: | hard |

| Certificate: | Intertek, ASTM, ISO9001, ITC | pattern: | parquet floor |

| usage: | Indoor and outdoor | Origin: | Zhejiang, China, CN; Zhejiang |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, different payment terms for different countries | Supply capacity: | 900 tons per month |

| thickness: | 22mm | Process: | wood plastic composite floor |

New design WPC flooring with grass outdoor garden

Model: | GWD02 |

size: | 300*300mm |

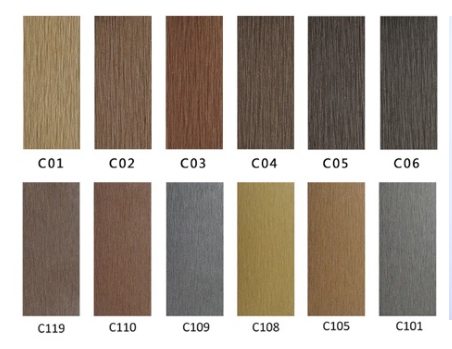

color: | Standard color and customized color |

Warranty: | 15-20 years old |

Type (hollow/solid) |

standard color

application

workshop

FAQ

1. What is the main ingredient of your WPC?

It is made of 60% recycled wood fiber, 30% recycled HDPE and 10% additives such as pigments, anti-UV agents, antioxidants, etc.

2. What wood species do you use for wood fiber?

Eucalyptus, poplar and some miscellaneous woods are related to color.

3. What is the temperature range that your WPC can be used in?

-40 to 60 degrees.

4. How about your WPC warranty?

15-year warranty. Guarantee can be sent.

5. Will your WPC fade?

To be honest, our WPC will have some discoloration in the first 6 months after installation, but it is not noticeable.

6. How about your main market?

Our focus is always on overseas markets. More than 90% of our products are exported, our main markets are Greece, Czech Republic, Italy, Germany, Spain, Austria,

Switzerland, Estonia, Norway, UK, Korea, Thailand, Indonesia, Vietnam, USA, Canada, Argentina, Australia, etc.

7. What are the advantages of solid floor compared to hollow floor?

Not too easy to crack.

Higher tensile strength.

Load-bearing deformation is small.

Water absorption is low.

Joist spans can be relatively large.

8. What is your co-extrusion wood plastic material?

Shielding layer (protective layer): engineering plastics.

Core material: wood plastic composite.

9. Which properties of your raw materials and final products will you test?

Wood fiber: ash content, fiber thickness, moisture content.

HDPE: Melt index, ash content, physical property test of finished product

Finished product: melt index, ash content, physical property test of finished product

Finished product: strength test, boiling test and expansion rate test, temperature cycle test, outdoor UV test.

10. How many production lines do you have? How about the monthly production capacity?

14 extrusion lines. 30-35 containers per month.

11. How many square meters. Deck can be loaded in 1x20GP container?

About 800 square meters. Deck, plus joists and fittings.

12. What about the delivery time for one container?

15-20 days after receiving the deposit.

13. What kind of certification do you have?

ISO9001, ISO14001, FSC certification.

As for the test report, there are test reports made according to EN15534 standard and ASTM standard.

Related Products

-

French Classic Solid Oak Mosaic Parquet Flooring Engineered Light Oak Flooring Geometric Design Oak Hardwood Flooring

Package: Customized carton + wooden pallet Product Name: Laminated Hardwood Flooring Brand Name: Youjia Supply Ability: 5000 square meters per day type: Indoor floor Material: oak Payment Terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging Details: Export seaworthy packaging. size: custom.... -

Hot selling gray AB grade solid wood composite flooring hardwood flooring oak flooring with cheap price

size: 1910×195×15mm model: QCW-MOT-NB1-195 Engineered Wood Flooring Types: Multilayer solid wood floor Place of origin: Zhejiang, China port: Shanghai grade: choose joint: Special & Special technology: Cold press and hot press payment terms: L/C, Western Union, T/T, PayPal After-sales service:...... -

Engineered Chevron Oak Flooring Hungarian Point Design Parquet Flooring

After-sales service: online technical support port: Shanghai Install: floating payment terms: L/C, Western Union, T/T, Alipay Finish: Treffert Scratch Resistant UV Lacquer Package preview: Material: oak product name: Chevron Oak Wood Floors Installation type: Special & Grid brand: enjoy wood Supply.... -

200 Models Designs Shapes Parquet Engineered Floating Floors Tap & Go Parquet Hardwood Engineered Wood Floors

Click System: T&G / Click to lock color: 50 colors to choose from Process: German technology, brushed/hand-painted/smooth/hand-painted/ Origin: Guangdong, China Supply capacity: 50000 square meters per month Engineered Wood Floor Types: Three layers of solid wood floor design style: modern...... -

Co-extruded wood-plastic composite flooring for Foshan swimming pool

After-sales service: inspect on the spot payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram model: SP-ML02 140*23 Packaging Details: Bulk or palletized Product Category: pavement Origin: Guangdong, China brand: Microcred Technology Package preview: usage: outdoor balcony port:...... -

20 Colors Customizable Wide Plank Washed Distressed Wood Flooring European White Oak Industrial Hardwood Laminate Flooring

Package preview: Engineered Wood Floor Types: Three-layer/multi-layer laminate flooring size: custom made Wear layer: UV paint payment terms: wire transfer application: bedroom/living room/villa/hotel, indoor model: Oak Series/Black Walnut Series thickness: 12/14/15 or custom Material: oak design...... -

200 special-shaped design parquet wood floor hexagonal mosaic composite floor

brand: natural rain product name: Special shape parquet Warranty: 5 years Wear layer: UV paint Supply capacity: 50000 square meters per month Click System: T&G / Click to lock Package preview: Origin: Guangdong, China model: Oak Series/Black Walnut Series payment terms: wire transfer Engineered...... -

New 2022 poplar parquet floors! Engineered White Oak Herringbone Flooring

Engineered Wood Floor Types: Multi-layer parquet usage: indoor use Packaging Details: Corrugated box + PE film + wooden pallet 1.365 square meters / carton 30KGS / carton MOQ: 100 square meters payment terms: Letter of credit, wire transfer, credit card length: 600mm port: Shanghai, Ningbo Supply...... -

1200mm long dimension high gloss floor 8mm 12mm laminate oak made in germany

port: Guangzhou/Shenzhen Material: MDF HDF MHDF payment terms: wire transfer model: NA series/ F4 series/ WJ series application: work from home Warranty: over 5 years Package: carton Certificate: CE/ISO9001/ISO14001 Core: MDF, MDF, HDF color: 12 colors in stock and custom colors design style:...... -

10 days delivery in stock supply european german white oak lumber engineer flooring hardwood engineered flooring

place of origin; place of origin: Guangdong, China Certificate: CE/ISO9001/ISO14001 port: Guangzhou Wear layer: UV paint Click System: T&G / Click to lock Packaging Details: 10 days delivery stock supply Europe German White Oak Lumber Engineered Flooring Hardwood Engineered Flooring Carton......