FLUTURA DASK AND EXTENSION OVAL DINING TABLE

- $236.00 / >=20 pieces

- 20 pieces

- HTS WOOD INDUSTRY COMPANY LIMITED

- Ho Chi Minh, China

- Mr mr Thai

Product Detail

| Packaging Details: | The standard is exported to the UK, which can meet the drop test requirements. First step we have PE board ==> then L safety bar around top and four corners out side legs ==> then styro foam 5mm ==> streth film ==> corner pads on legs ==> carton 5 layers. | fold: | Yes |

| Mail packing: | yes | brand: | Painted HTS01 |

| delivery time: | 45 days | Supply capacity: | 500 pieces per month |

| type: | restaurant furniture | port: | ho chi minh |

| Package preview: | design style: | European | |

| model: | 2022 | Origin: | Ho Chi Minh City of Vietnam |

| feature: | adjustable (other) | application: | kitchen, living room, dining room |

| appearance: | modern | payment terms: | L/C, D/P, T/T |

| Wood Style: | solid wood | Material: | wood |

| General use: | home furniture |

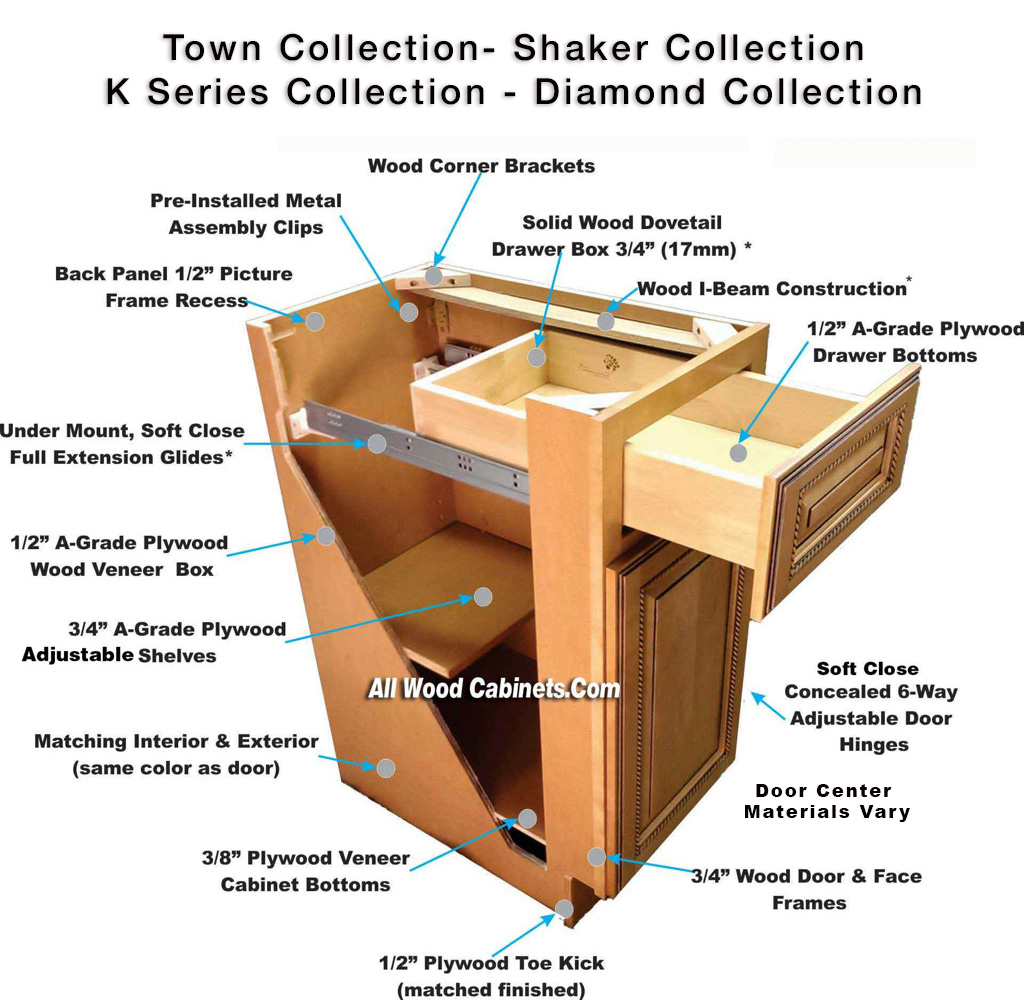

*** Material and structure

-topMade of white oak mixed MDF Venner Oak imported from USA, invisible details are made of NZ Pine

=>CNCFinishing in Natural Color - Waxed Oak - Oil - Glazed Oak....

-baseMade of NZ Pine mix MDF (Carb P2)

=>PolyurethaneMultiple color finishes for the customer to choose such as White, Cream Grey, Ivory... base color Ral

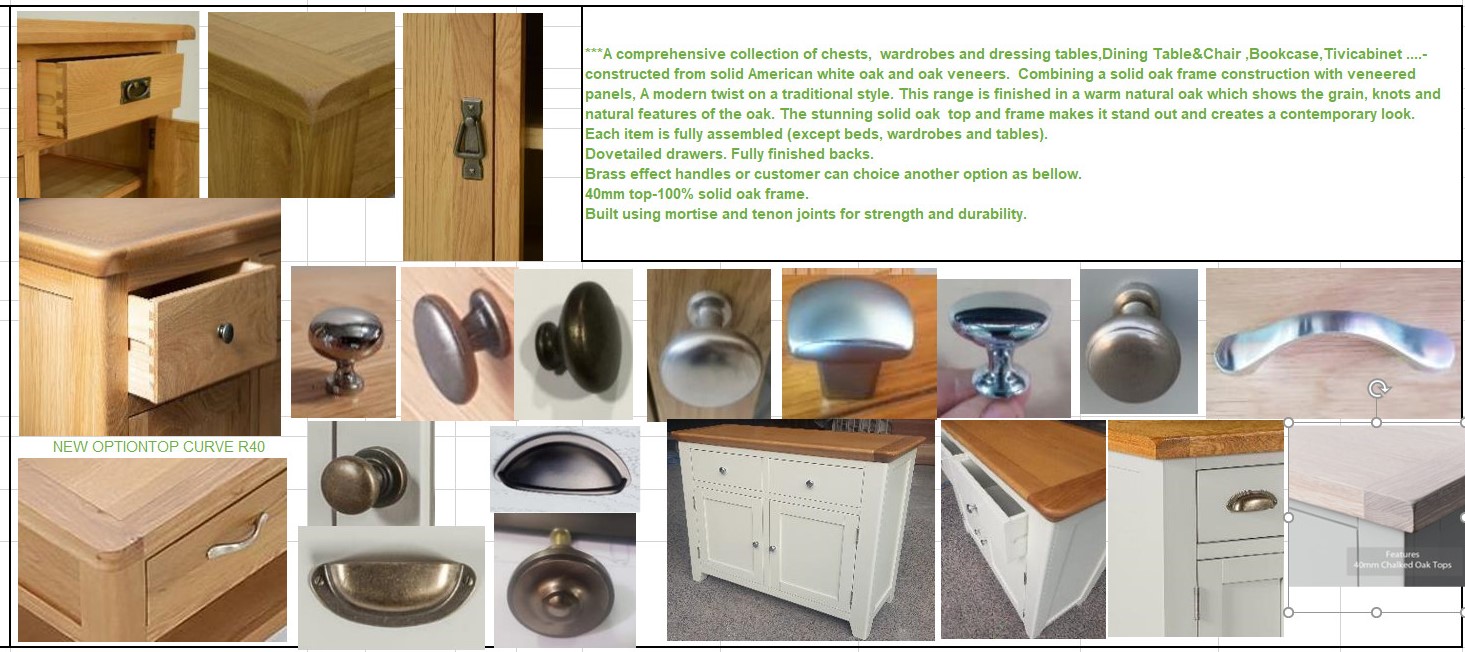

- Wooden bottoms or sides of drawers and drawers with dovetail construction.

- All structures are made of inert wood and wood or planks with tenons or dowels....

The standard is exported to the UK, which can meet the drop test requirements. First step we have PE board ==> then L safety bar around top and four corners out side legs ==> then styro foam 5mm ==> streth film ==> corner pads at legs ==> Carton 5 layers.

1. DesignBased on the new series of client's idea, make 3D drawing to show the appearance. => Make a sample => Finish the sample...

2. DevelopmentFull range including detail drawings, bill of materials, paintings...

3.Imported manufacturingGood quality products can be produced in Vietnam, you can use our service to guarantee the product quality before loading the container.....

4. Quality control QC/QANursing production online.

-Check the thickness of each wooden strip according to the detail drawing before assembly. Make sure all dimensions must be the same as your approved drawings.

- Check the quality of every detail of the product before assembly, all poor quality details need to be rejected immediately.

- Test the structure after assembly. Make sure the structure is strong enough at the joints. The amount of glue is sufficient and the quality is good.

- Assembled test structures, the exterior and interior must be cleaned prior to the sanding step.

- Check that the product color must be like the color sample approved by the customer, check the side and inside after the packaging is completed.

- All products of the same style must be similar in color and everything.

- Check how it is packaged to ensure product safety. The inspection container must be clear before loading. Check which items will be loaded on the container. Check the container one last time before it leaves.

***after loading

-

We will notify you of this container after it leaves, such as packing list, ETD, ETA, inspection report...

.

All of our services are "for the care of the product" and there is a 3% fee per order.

Haitongsi Wood Industry Co., Ltd.

- Phone number: +84 915 850386 (Mr. Tai - Manager)

- WeChat: Thaiho850386

- WeChat: +84 915 850386

- Zalo: +84 915 850386

- Email: [email protected]

Related Products

-

Custom New Design Furniture Living Room Rectangular Side Table Gold Leg Marble Top Console Table Modern

Mail packing: yes design style: minimalist type: restaurant furniture fold: No feature: adjustable (other) payment terms: wire transfer usage: relax leisure time decoration General use: home furniture Package preview: Supply capacity: 1000 pieces per month appearance: modern application: Kitchen,...... -

UK Best Selling Factory Price Direct Supplier Low MOQ Customized Heavy Duty Luxury Home Decor Shape Shelf Decor Export

application: Kitchen, bathroom, home office, living room, bedroom, hotel delivery time: 7 days Material: Metal type: restaurant furniture MOQ: 1 product name: Luxury Home Decor Shape Shelf Decor UK Bestseller Mail packing: yes Packaging Details: Full size: 30x185x30cm, delivered folded. port:...... -

2 chests of drawers or more 4 chests of drawers

Material: wood Supply capacity: 500 pieces per month fold: Yes Wood style: solid wood Mail packing: yes delivery time: 45 days payment terms: L/C, D/P, T/T appearance: modern General use: home furniture type: restaurant furniture Origin: Ho Chi Minh City of Vietnam brand: Painted HTS01 design...... -

Nordic modern minimalist solid wood rotating bar stool home bar island table high bar stool

MOQ: 1 Material: wood application: Catering, office building Mail packing: yes appearance: modern type: restaurant furniture Packaging Details: Closed wooden box packaging design style: contemporary feature: minimalist bar chair usage: dinner Origin: China Shanghai color: custom color General use:..... -

Factory Supplier High Quality Latest Professional Home Luxury Home Furniture Decoration Shape Home Table Decoration

Packaging Details: Folded for delivery. General use: home furniture application: Kitchen, bathroom, home office, living room, bedroom, dining room, hotel feature: adjustable (other) Origin: turkey Mail packing: yes MOQ: 1 fold: Yes payment terms: L/C, Western Union, T/T, Wise delivery time: 7 days..... -

Factory Direct Wholesale Standard Custom Stainless Steel Frame Console Table Modern Luxury

port: Guangzhou Shenzhen Furniture Style: console table gold application: Kitchen, home office, living room, bedroom, dining room, outdoor, hotel, apartment, office building, hospital, school, sports venue, leisure facility, supermarket, warehouse, workshop, park, farmhouse, courtyard, exterior,...... -

Luxury Morden Style PU High Chair Grass Leather Bench With Metal Arm Base

Mail packing: yes Package preview: product material: Metal+PU product name: bar chair model: 4BC001 payment terms: Western Union, D/P, D/A, T/T, MoneyGram port: Tianjin type: restaurant furniture Package: cardboard box delivery time: 7 days General use: home furniture color: Black MOQ: 5 Origin:...... -

Swivel Chair Golden Polished Stainless Steel Wooden High Back Bar Chair Stool Upholstered Velvet Fabric Cushion Yuan Pedal

Wood Style: solid wood type: restaurant furniture model: QS750 swivel bar chair application: Kitchen, home office, living room, bedroom, dining room, hotel, apartment, office building, hospital, shopping mall, sports venue, leisure facility, supermarket, park, courtyard, locker, wine cellar, lobby,.... -

Strine's simple mobile dining car multi-functional teahouse kitchen wine car double-layer small meal sidebar dining car

type: restaurant furniture application: kitchen, hotel, apartment, warehouse design style: modern Material: Glass General use: home furniture model: SG-Kanche Origin: Guangdong, China payment terms: letter of credit brand: Very good Mail packing: yes Product Description Packing and shipping Related.... -

Best Choice Newest Professional New Factory Home Furniture Home Luxury Decoration Book Shelves Decoration Export

Mail packing: yes General use: home furniture feature: Folding design style: modern application: Kitchen, bathroom, home office, living room, bedroom, hotel Material: Metal port: turkey brand: No branding/custom labeling MOQ: 1 Origin: turkey product name: Luxury Home Decor Shape Shelf decor UK......