6.38mm Fabric/Etched Laminated Tempered Art Glass Tempered Laminated Stained Architectural Glass Wall Architectural and Industrial Glass

-

$16.90 / 2 - 49 square meters

$10.90 / 50 - 199 square meters

$4.90 / >=200 square meters - 2 square meters

- Shenzhen Huifeng Trade Co., Ltd.

- Guangdong, China

- Mr Steve Xu

Product Detail

| technology: | Transparent/painted/coated/patterned/interlayer/dyed/tempered/colored glass | product name: | architectural stained glass |

| Type one: | silk screen glass | Type 2: | Printed tempered glass |

| model: | ASG03 | Certificate: | CE CCC certificationISO |

| Project solution ability: | Graphic design | Glass color: | Yellow, blue, red, green, etc. can be customized |

| shape: | flat | application: | Yards, leisure facilities, supermarkets, farmhouses, laundry rooms, workshops, kitchens, schools, bathrooms, babies and children, bedrooms, outdoors, dining rooms, warehouses, home offices, stairs, outdoors, living rooms, parks, wine cellars, offices, storage rooms & closets, gyms, malls, entrances, apartments, sports venues, basements, hospitals, villas, hotels, home bars, halls, garages and sheds |

| place of origin; place of origin: | Guangdong, China | After-sales service: | Return and exchange, online technical support, free spare parts |

| feature: | High strength, safety, toughness | Type 3: | 3D printed glass |

| port: | Shenzhen | Supply capacity: | 10,000 square miles per week |

| usage: | Industrial, medical, decoration, solar energy, greenhouse, curtain wall, railing, imaging, lighting, bulletproof, display, instrumentation | Function: | Acid etched glass, decorative glass, heat treatment |

| Warranty: | over 5 years | application: | Supermarket, bathroom, bedroom, living room, office building, shopping mall |

| Packaging Details: | Step 1. Protective tape to protect the frame from scratches; Step 2. Fix the window on the wooden pallet; Step 3. Use plastic tape to tie the window on the wooden pallet Step 4. PE film to keep the window away from sea water; Step 5 , fill the space between every two wooden pallets with airbags; the sixth step, use plastic straps to tie up the wooden pallets in the container. Our packages will ensure the windows arrive at the project site intact, please contact us for package details and we will show you the pictures. | thickness: | 5mm - 500mm |

| brand: | HSBC | structure: | solid, hollow |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

6.38mm Fabric/Etched Laminated Tempered Art Glass Tempered Laminated Stained Architectural Glass Wall Architectural and Industrial Glass

Product Description

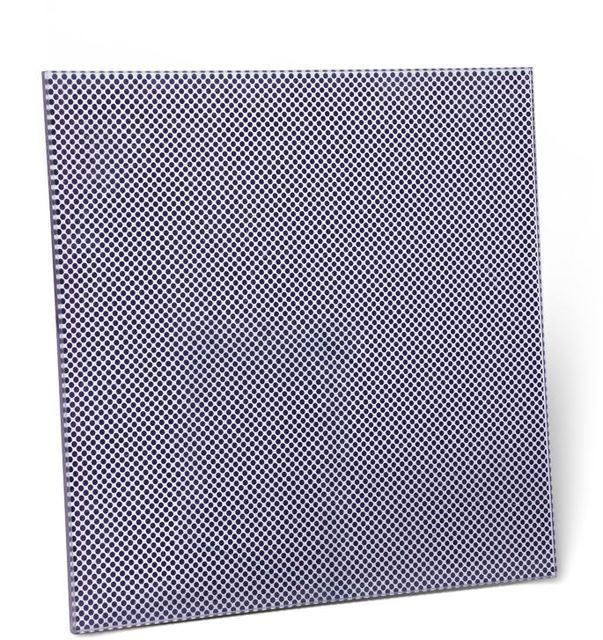

Ceramic digital printing screen printing

Ceramic digital printing screen printing glass is actually coated with a specific color glaze on the glass surface and used

Proper heat treatment process permanently fixes the glaze layer on the glass surface. Not only is it beautifully patterned,

It has good decoration, acid and alkali resistance, aging resistance and stability, easy to clean, not easy to

fade. It is a commonly used building decoration material in the construction field. along with

With the improvement of domestic social consumption level, glazed glass not only appears in the field of high-end commercial buildings

Whether it is high-end furniture decoration or ordinary architectural decoration, it has been widely used and used.

Proper heat treatment process permanently fixes the glaze layer on the glass surface. Not only is it beautifully patterned,

It has good decoration, acid and alkali resistance, aging resistance and stability, easy to clean, not easy to

fade. It is a commonly used building decoration material in the construction field. along with

With the improvement of domestic social consumption level, glazed glass not only appears in the field of high-end commercial buildings

Whether it is high-end furniture decoration or ordinary architectural decoration, it has been widely used and used.

Chinese ceramic porous glass is rich in various patterns. Color and pattern can be customized

Require. As an important decorative material, ceramic gravel glass has excellent decoration and stability, and is easy to clean.

And not easy to fade. Has a strong application value. Therefore Chinese ceramic porous glass manufacturers will design different

Patterns and colors depend on customer's requirements.

Require. As an important decorative material, ceramic gravel glass has excellent decoration and stability, and is easy to clean.

And not easy to fade. Has a strong application value. Therefore Chinese ceramic porous glass manufacturers will design different

Patterns and colors depend on customer's requirements.

Wide range of use, stable color, aging resistance, acid and alkali resistance, no fading, good decorative effect

outstanding.

outstanding.

At the same time, it can absorb and reflect part of the sun's heat. Different heat treatment methods can be used to obtain glass products with different functions. Ceramic sintered glass can be further processed such as interlayer, interlayer, hollow out, etc., with more functions and effects. Not only ceramic porous glass, but also curved glass.

Stained glass printing method: screen printing/digital printing/3D printing glass

screen printing

Ceramic frit glass is also called colored glaze glass. It is inorganic colored glaze glass that is glazed on the glass surface by roller printing or screen printing machine, and then dried and tempered to make the colored glaze permanently sintered on the glass surface. After anti-oxidation treatment . Acid and alkali safety and new decorative glass materials.

digital printing

Semi-automatic PET Blow Molding Machine Blow Molding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in various shapes.

3D printed glass

3D digital printing glass is a combination of tempered glass with the latest digital printing technology, using ceramic ink/frit to melt into the glass, which has the characteristics of anti-ultraviolet/anti-ultraviolet. It enables you to escape the traditional limitations of screen printing and non-ceramic digital printing technologies.

Thickness: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm, 22mm, 25mm.

Color: white, black, green, red, blue, all colors can be done, according to PANTONE color or RAL color

Size: custom size, according to raw glass size

Application: Patition Trim, Railing, Shower Door, Curtain Wall...

About Printed Glass

Print in high definition directly on glass with our ImageVue print-on-glass printing option. With a full color spectrum up to 1200 DPI, we can print images and designs that are truly vibrant on glass up to 110” x 62”. Choose printed glass for windows or privacy dividers that enhance imaging. Perfect for barn doors, glass shower doors, and glass table tops. Choose between different levels of opacity and density for the perfect finish. Printed glass is a true example of applied art.

Our ImageVue glass printing service allows you to submit your own artwork or any design using our decorative glass

library. Scale, rotate, change colors and add effects to patterns and print directly onto glass to create your unique creation

project. For a deeper level of creativity, combine our other glass services such as etched glass, backpainting and LED lighting.

library. Scale, rotate, change colors and add effects to patterns and print directly onto glass to create your unique creation

project. For a deeper level of creativity, combine our other glass services such as etched glass, backpainting and LED lighting.

Competitive advantages:

1. There are many kinds of silk screen glass products, and various customized patterns and colors can be applied.

2. Scratch resistance, acid and alkali resistance

3. High color stability, durable and no fading

4. Safety glass has the ideal properties of tempered glass

5. Effective sunshade.

glass processing

cut glass

Next to it you can see a CNC cutting line, which is controlled by the AutoCAD file (.dxf file). Therefore, your glass

Products can be processed in close to 1:1 ratios, keeping tolerances to a minimum.

Products can be processed in close to 1:1 ratios, keeping tolerances to a minimum.

glass polishing

Glass polishing can smooth and/or shine the sharp sides of the glass and reduce the accuracy to +/- 0.5 mm. When polishing glass, there are several possibilities that can produce different results. Below is a list of these possibilities.

Ground and polished flat edges

The major part of cutting is performed partially or fully automatically. On our Intermac cutting tables we can cut small sizes

Automatic amount.

Automatic amount.

Bump polishing

In addition to conventional polishing, we can also grind glass to a convex or concave surface. By this cutting method, the glass obtains

Rounded (convex) or hollow (concave). This operation is usually used for hard glass walls, where there are different glass panes

must be directly connected to each other. Thanks to the hollow and round sides, they "slide into each other", making them

There is no need to seal them. This creates a very stable wall with barely visible seams.

In addition to conventional polishing, we can also grind glass to a convex or concave surface. By this cutting method, the glass obtains

Rounded (convex) or hollow (concave). This operation is usually used for hard glass walls, where there are different glass panes

must be directly connected to each other. Thanks to the hollow and round sides, they "slide into each other", making them

There is no need to seal them. This creates a very stable wall with barely visible seams.

faceted polishing

A facet is a beveled edge of a given width at the edge of the glass. Almost any type of glass, in almost any quantitythickness, can be equipped with sharp faceted edges. Because it is cut at a certain degree, the edge of the glass becomes

Thinner as facets get wider. The thicker the glass, the wider the facets that can be made. Facets can be made on straight glass

plates, and a plate of a different shape.

Depending on the thickness, the facet width can vary from 0.5mm to 45mm.

miter cut

Beveling is the same application as polishing. However, when polishing the facets, the disk presses against the glass

At a (variable) angle from 0 to 67.5 degrees. The thick sides of the glass are ground and/or polished. maybe one

Reserve the residual value.

CNC polishing

This polishing operation is also a secondary process, especially used in models. There must be enough space for the

sucker. Tolerance amounts start from +/- 1mm depending on thickness.

Beveling is the same application as polishing. However, when polishing the facets, the disk presses against the glass

At a (variable) angle from 0 to 67.5 degrees. The thick sides of the glass are ground and/or polished. maybe one

Reserve the residual value.

CNC polishing

This polishing operation is also a secondary process, especially used in models. There must be enough space for the

sucker. Tolerance amounts start from +/- 1mm depending on thickness.

glass milling

With our advanced CNC machines, we can mill a variety of shapes and notches into the glass bed.

CNC cutting

Next to it you can see a CNC cutting line, which is controlled by the AutoCAD file (.dxf file). Therefore, your glass

Products can be processed in close to 1:1 ratios, keeping tolerances to a minimum.

With our advanced CNC machines, we can mill a variety of shapes and notches into the glass bed.

CNC cutting

Next to it you can see a CNC cutting line, which is controlled by the AutoCAD file (.dxf file). Therefore, your glass

Products can be processed in close to 1:1 ratios, keeping tolerances to a minimum.

glass drilling

By doing this we can punch holes in the glass. This is done from both sides, which means drilling from the top and bottom

from the bottom. Drilled 50% from the top side and 60% up from the bottom on the other side resulting in a beautiful finished diamond

Hole. With conical finishing, a bevel can be milled into the drilled hole.

glass engraving

Decorations can be engraved on the glass. These engravings can actually come in various forms; the width of the engraving is,

However, up to 5 mm. Glossy engraving is possible.

By doing this we can punch holes in the glass. This is done from both sides, which means drilling from the top and bottom

from the bottom. Drilled 50% from the top side and 60% up from the bottom on the other side resulting in a beautiful finished diamond

Hole. With conical finishing, a bevel can be milled into the drilled hole.

glass engraving

Decorations can be engraved on the glass. These engravings can actually come in various forms; the width of the engraving is,

However, up to 5 mm. Glossy engraving is possible.

tempered glass

By tempering glass, also known as stretching, we were able to increase the structural strength by a factor of 4. Then

Becomes safety glass that breaks down into small pieces when broken. This is achieved under the DIN standard.

glass UV gluing

When using UV gluing, a bond is created between glass/glass and glass/metal. Connections are made via optical keys

Glue highlighted in the UV-A range. The frequency used is about 380 Nm. many connections made

Stronger than glass.

By tempering glass, also known as stretching, we were able to increase the structural strength by a factor of 4. Then

Becomes safety glass that breaks down into small pieces when broken. This is achieved under the DIN standard.

glass UV gluing

When using UV gluing, a bond is created between glass/glass and glass/metal. Connections are made via optical keys

Glue highlighted in the UV-A range. The frequency used is about 380 Nm. many connections made

Stronger than glass.

glass screen printing

Screen-printed glass can always create surprising effects in modern architecture. glass bond

Color and light open up many creative possibilities for designing interior spaces and facades. with screen

With typographic decorations such as text, repeated abstract forms and colorful images, the creative possibilities seem endless.

Screen printing is often used for repetitive jobs.

Color and light open up many creative possibilities for designing interior spaces and facades. with screen

With typographic decorations such as text, repeated abstract forms and colorful images, the creative possibilities seem endless.

Screen printing is often used for repetitive jobs.

The glass is printed with ceramic paint using screen printing technology. The paint is fired on the glass at +/- 600 °C with excellent adhesion between ceramic paint and glass. This way of working ensures that even with solvents the color cannot be removed from the glass. There is also no discoloration from sun exposure. By firing the paint at high temperatures, the glass also acquires the mechanical and thermal properties of a single safety glass. These colored panels can also be further processed into laminated and/or insulating glass. Most Ral colors are available. Building facades, coatings, windows, roofs, glass railings, partition walls or wall coverings for bathrooms and kitchens. Our standard range of finishes already offers a multitude of possibilities. Customized decorations, personal photos, company logos and personal themes are all possible according to your needs and wishes. The screen-printed pattern can also be used as anti-slip glass for people to walk on.

Glass digital printing

The application of digital printers is the latest development in the field of interior glazing. The technology continues to improve so that larger glass surfaces can be printed, printing has become more sustainable and UV resistant, and brightness and pixel count have also increased, positively affecting image quality. A relatively new innovation on the market is digital printing on PVB films for laminated glass.

more products

Specification

thing | value |

place of origin; place of origin | Guangdong, China |

brand | HSBC |

model | ASG01 |

Warranty | over 5 years |

shape | flat |

structure | solid, hollow |

After-sales service | Returns, online technical support, free spare parts |

Project solving ability | Graphic design |

application | Yards, leisure facilities, supermarkets, farmhouses, laundry rooms, workshops, kitchens, schools, bathrooms, babies and children, bedrooms, exteriors, restaurants, warehouses, home offices, stairs, outdoors, living rooms, parks, wine cellars, office buildings, storage Rooms & closets, gyms, shopping centers, entrances, apartments, sports venues, basements, hospitals, villas, hotels, home bars, halls, garages and sheds |

usage | Industrial, medical, decorative, solar, greenhouse, curtain wall, railing, imaging, lighting, bulletproof, display, instrumentation |

thickness | 5mm - 500mm |

product name | architectural stained glass |

Type 1 | silk screen glass |

application | Supermarket, bathroom, bedroom, living room, office building, shopping mall |

Type 2 | Printed tempered glass |

Type3 | 3D printed glass |

Certificate | CE CCC certificationISO |

feature | High strength, safety, toughness |

technology | Transparent/painted/coated/patterned/interlayer/dyed/tempered/colored glass |

Function | Acid etched glass, decorative glass, heat treatment |

glass color | Yellow, blue, red, green, etc. can be customized |

VIEW MORE

Related Products

-

4mm 5mm 6mm 8mm 10mm 12mm tinted reflective float glass European bronze dark gray stained glass doors and windows

Product Description Coated glass (reflective glass), also known as reflective glass. Coated glass is to coat one or more layers of metal, alloy or metal compound films on the surface of the glass to change the optical properties of the glass to meet certain specific requirements.Online sunlight...... -

China's largest float tinted black gray glass flat glass factory

edge: Finely polished edges brand: Tianyao Packaging details: Secure wooden or plywood crate packaging suitable for sea and land shipping. The crates are very sturdy and every loading worker has at least 5 years of experience. Package preview: Project solution capabilities: Overall project solution.... -

China Wholesale Reflective Glass Bronze Gray Blue Green Reflective Glass Color Reflective Glass

Project Solution Capabilities: graphic design thickness: 4mm, 5mm, 6mm, 8mm, etc., 3mm-12mm Origin: Hebei china quality: First grade After-sales service: online technical support model: colored glass, tinted glass Certificate: ISO9001 expiration of pay: Electrox/Liquid Chromatography raw material:..... -

Hot Sale High Quality Probe High Quality Ocean Brown Automatic Tinted Glass

structure: hard Warranty: 1 year brand: Sanda application: Yards, leisure facilities, supermarkets, farmhouses, laundry rooms, workshops, kitchens, schools, bathrooms, infants, bedrooms, outdoors, dining rooms, warehouses, home offices, stairs, outdoors, living rooms, parks, wine cellars, office...... -

China glass factory, transparent colored reflective architectural windows architectural glass

model: AH Building Material: Transparent glass, tempered glass, laminated glass, reflective glass usage: Industry, Decoration, Greenhouse, Curtain Wall After-sales service: Returns and Exchanges technology: Transparent glass Warranty: 1 year application: Architectural glass, roofs, domes, windows,..... -

Dark gray painted decorative glass

thickness: 1mm-19mm brand: Tian Yao shape: flat After-sales service: Online technical support, on-site training Package preview: port: Tianjin/Qingdao/Shanghai Warranty: over 5 years Origin: Hebei china expiration of pay: 30% T/T advance payment model: 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm, colored...... -

4mm 5mm 6mm 8mm colored float glass colored float glass blue green brown float glass doors and windows

Supply capacity: 10000 square meters per day Package preview: Project solution ability: Project overall solution, 3D model design, others, cross-category integration, graphic design usage: industrial, decorative payment terms: wire transfer structure: hard port: Tianjin application: Office...... -

Factory direct sales in 2023 the latest technology color laminated glass laminated tempered glass colored glass

Warranty: 1 year thickness: 3mm-30mm After-sales service: Return and exchange, online technical support, free spare parts port: Shenzhen - Yantian structure: solid, hollow application: Yards, leisure facilities, kitchens, schools, bathrooms, bedrooms, exteriors, home offices, stairs, outdoors,...... -

Transparent glass block low price multi-color hot melt crystal brick building glass block glass block size 200*100*50MM

After-sales service: not any Project solution ability: Project overall solution, 3D model design structure: hard color: custom color shape: flat Gross weight per piece: 2.500 kg application: Courtyard, bathroom, dining room, home office, outdoor, living room, park, wine cellar, office building,...... -

High quality and low price glass brick 190*190*80mm 145*145*80mm decorative glass hollow glass brick

Project solution ability: not any quality: upscale port: Shenzhen - Yantian Glass application: Door and window glass partition structure: solid, hollow model: glass brick Other glasses we supply: Laminated glass brand: Yao Yu Glass Origin: Guangdong, China technology: stained glass application:......